aluminium honeycomb sandwich panel

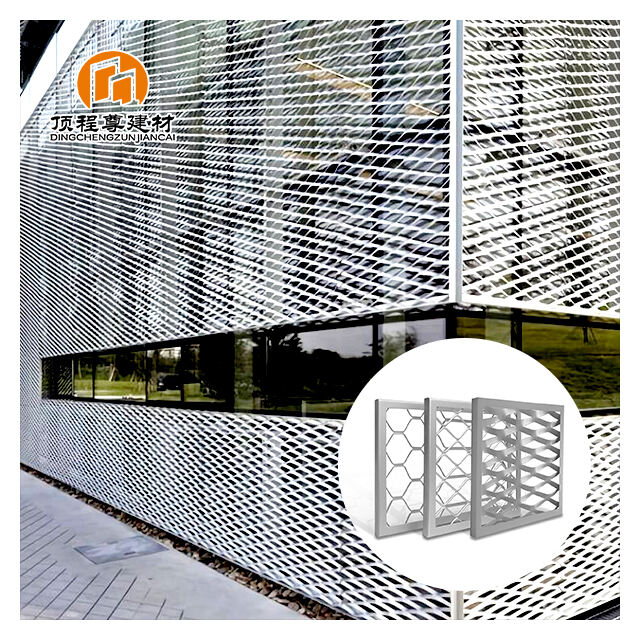

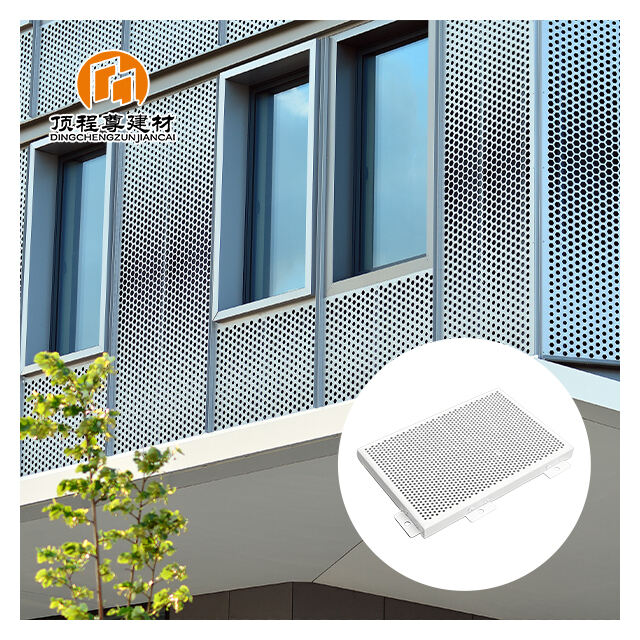

The aluminum honeycomb sandwich panel represents a revolutionary advancement in construction and engineering materials, combining lightweight properties with exceptional strength. This innovative composite structure consists of two thin aluminum face sheets bonded to a honeycomb core, creating a panel that delivers superior performance characteristics. The hexagonal cell structure of the core mimics nature's most efficient design, providing maximum strength with minimal material usage. These panels are engineered to offer remarkable stability and rigidity while maintaining an incredibly low weight-to-strength ratio. The manufacturing process involves precision bonding techniques that ensure perfect adhesion between the face sheets and the honeycomb core, resulting in a unified structure that performs as a single unit. The panels exhibit excellent resistance to compression, shear, and bending forces, making them ideal for applications where structural integrity is paramount. In the transportation sector, these panels are extensively used in aircraft interiors, marine vessels, and high-speed trains. The construction industry utilizes them for facade systems, clean rooms, and architectural applications. The panels also demonstrate exceptional thermal insulation properties and sound dampening capabilities, contributing to their versatility across different applications. Their corrosion resistance and ability to withstand diverse environmental conditions further enhance their appeal for both interior and exterior applications.