aluminium honeycomb composite panel

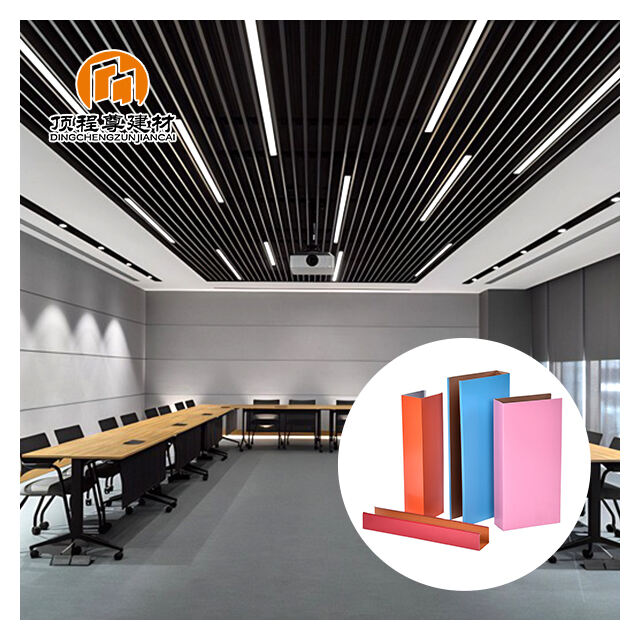

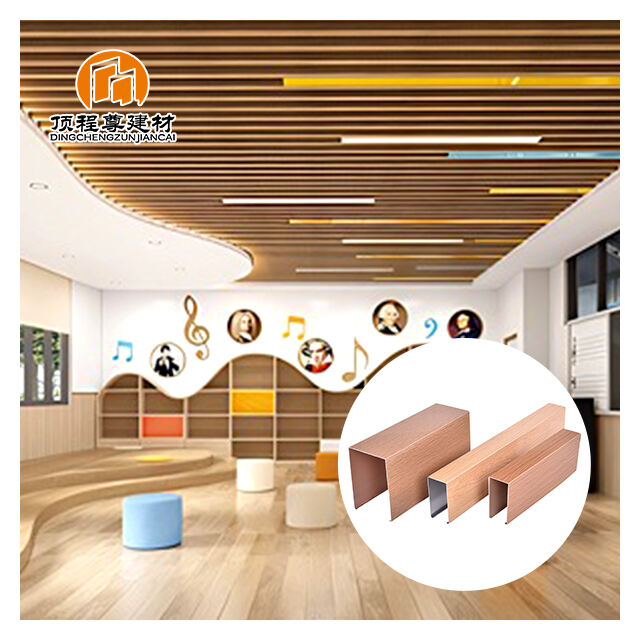

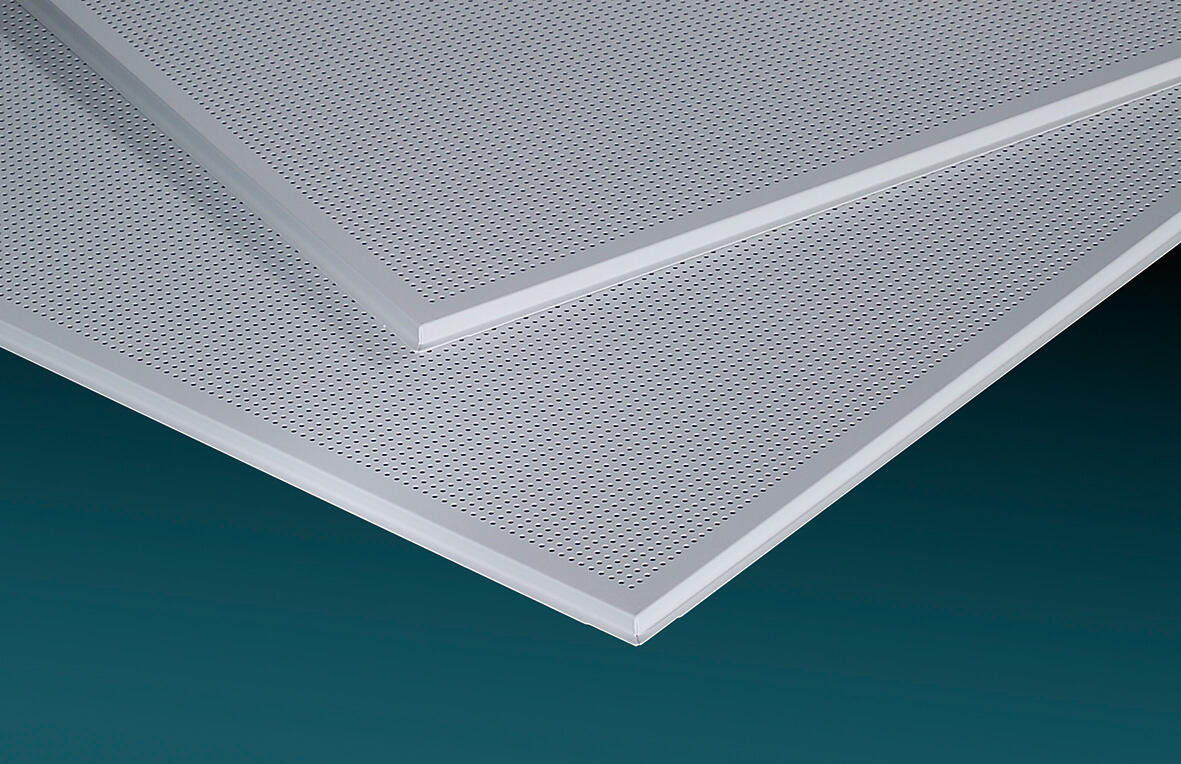

Aluminum honeycomb composite panels represent a revolutionary advancement in construction and architectural materials, combining lightweight properties with exceptional strength. These panels consist of three main components: two aluminum face sheets and a honeycomb core structure. The core features hexagonal cells that mimic the natural efficiency found in beehives, creating a remarkably stable and durable structure. The manufacturing process involves bonding high-grade aluminum sheets to the honeycomb core using advanced adhesive technology, resulting in a panel that offers superior strength-to-weight ratio. These panels excel in applications requiring high structural integrity while maintaining minimal weight, making them ideal for modern construction projects. The panels demonstrate remarkable resistance to bending and compression forces, providing excellent rigidity and dimensional stability. Their unique structure allows for effective load distribution across the entire panel surface, enhancing their structural performance. Additionally, the panels offer outstanding flatness and thermal stability, making them suitable for diverse environmental conditions. In industrial applications, these panels have become increasingly popular for clean rooms, partition walls, and ceiling systems, where their combination of strength and lightweight properties proves invaluable. The panels also feature excellent sound absorption and vibration dampening characteristics, contributing to improved acoustic performance in various settings.