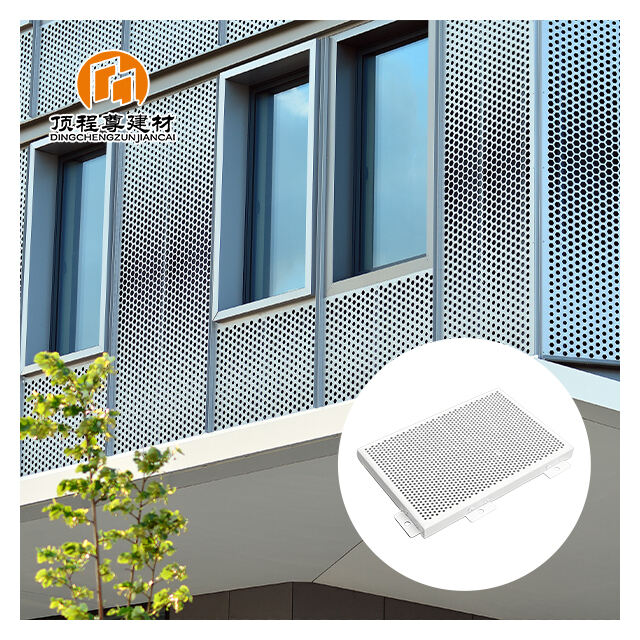

aluminum honeycomb composite

Aluminum honeycomb composite is an advanced engineering material that combines lightweight properties with exceptional structural strength. This innovative material consists of a core structure made from aluminum foil formed into hexagonal cells, resembling a natural honeycomb, sandwiched between two aluminum face sheets. The unique geometric arrangement of cells provides remarkable strength-to-weight ratios while maintaining structural integrity. The manufacturing process involves bonding thin aluminum foils together and expanding them to create the characteristic hexagonal pattern. This configuration allows for optimal distribution of mechanical stress across the entire structure, resulting in superior load-bearing capabilities. The material exhibits excellent resistance to compression and shear forces, making it ideal for applications requiring high structural performance with minimal weight. In aerospace and transportation industries, aluminum honeycomb composites are extensively used in aircraft floors, helicopter rotor blades, and high-speed train components. The construction sector benefits from its application in architectural panels, clean room walls, and elevator platforms. Additionally, the material's inherent properties provide exceptional thermal insulation and sound dampening characteristics, making it valuable in environments where temperature control and noise reduction are crucial. The versatility of aluminum honeycomb composite extends to marine applications, where its corrosion resistance and durability make it suitable for boat decking and bulkheads.