aluminum honeycomb panels price

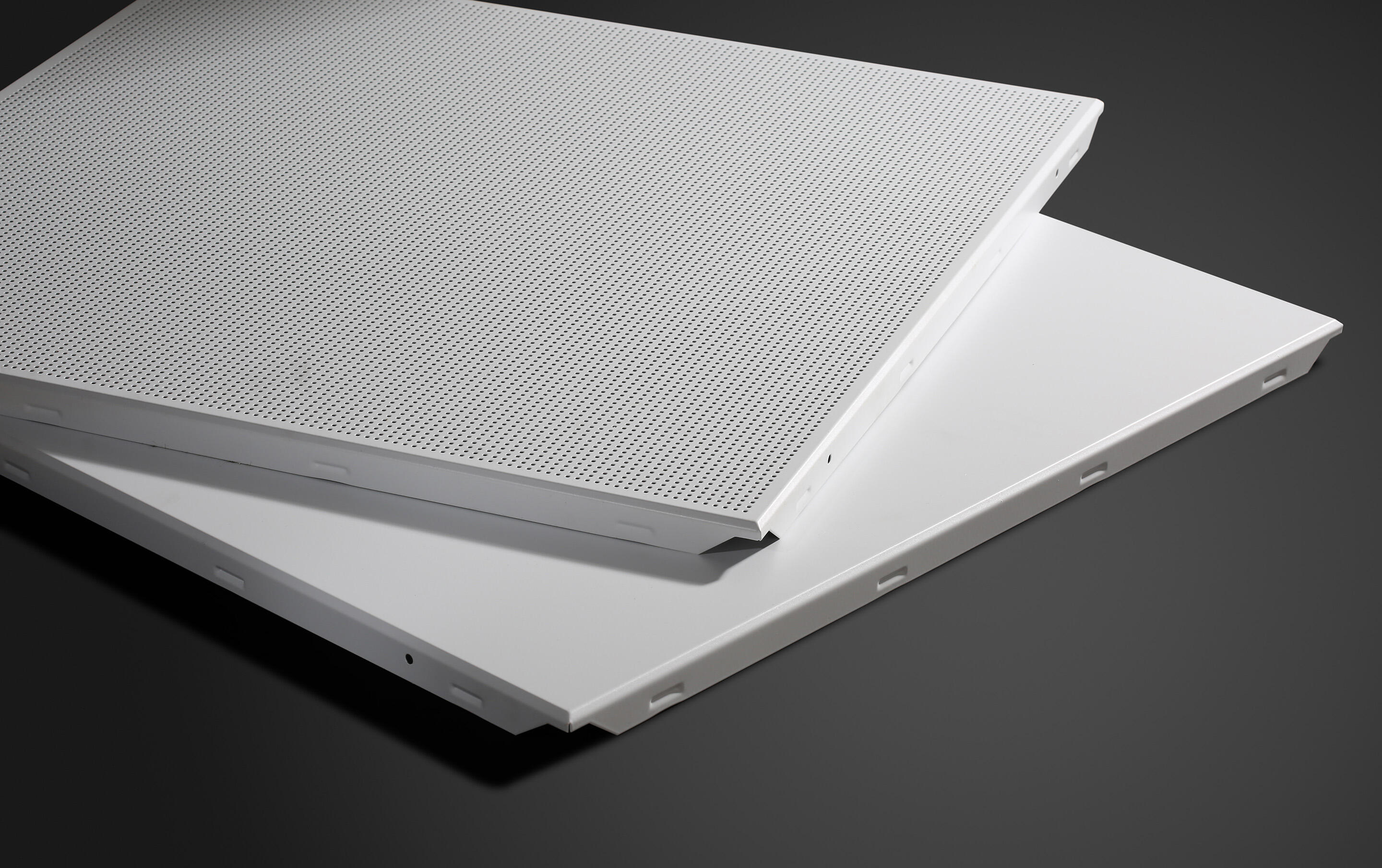

Aluminum honeycomb panels represent a significant advancement in construction and architectural materials, with prices varying based on quality, specifications, and market demands. These panels typically range from $15 to $50 per square meter, offering exceptional value considering their remarkable strength-to-weight ratio. The price structure reflects the sophisticated manufacturing process, which involves bonding two aluminum face sheets to a hexagonal core structure. This creates a lightweight yet incredibly strong composite material that finds applications across various industries. The pricing considerations include factors such as panel thickness (ranging from 5mm to 50mm), cell size (typically 3mm to 19mm), and surface treatment options. Premium grades used in aerospace applications command higher prices, while commercial construction variants are more economically priced. Manufacturers often offer customization options, including different surface finishes, core densities, and panel dimensions, which can influence the final cost. The durability and longevity of these panels often justify their initial investment, as they require minimal maintenance and provide excellent thermal insulation properties.