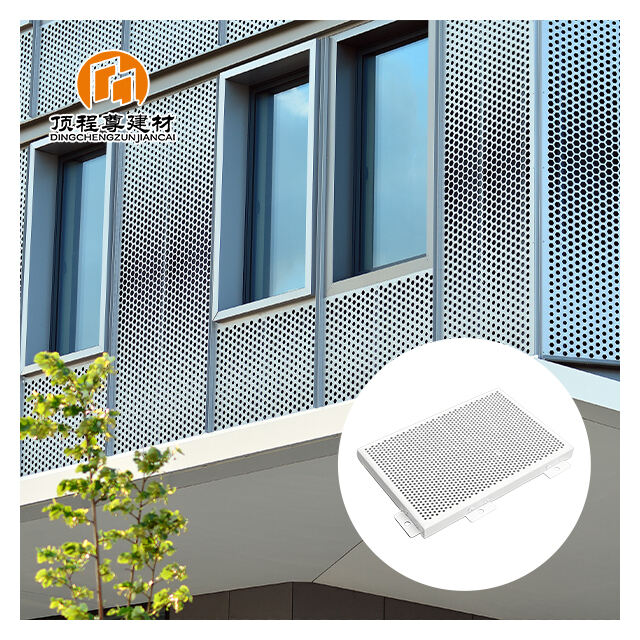

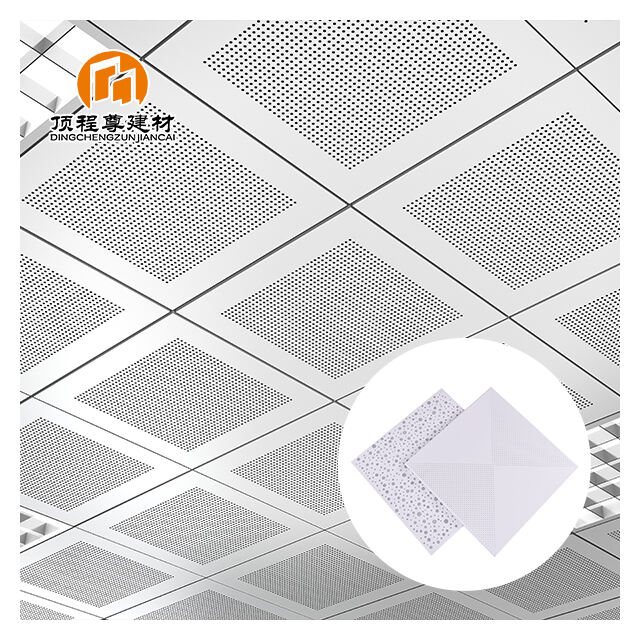

aluminum honeycomb composite panel

Aluminum honeycomb composite panels represent a revolutionary advancement in construction and architectural materials, combining lightweight design with exceptional strength. These panels consist of three primary layers: two aluminum face sheets sandwiching a honeycomb core structure. The hexagonal cell pattern of the core, reminiscent of natural beehives, provides remarkable structural integrity while maintaining minimal weight. The manufacturing process involves bonding high-grade aluminum sheets to the honeycomb core using advanced adhesive technologies, creating a unified panel that offers superior performance characteristics. These panels excel in applications requiring high strength-to-weight ratios, making them ideal for modern architecture, transportation, and industrial uses. The unique composition allows for excellent thermal insulation, sound dampening, and resistance to environmental factors. Additionally, the panels demonstrate exceptional flatness and dimensional stability, crucial for large-scale architectural applications. Their versatility extends to various finishing options, including different colors, textures, and surface treatments, allowing architects and designers to achieve both functional and aesthetic objectives. The panels' inherent fire resistance and recyclability further enhance their appeal in sustainable building projects.