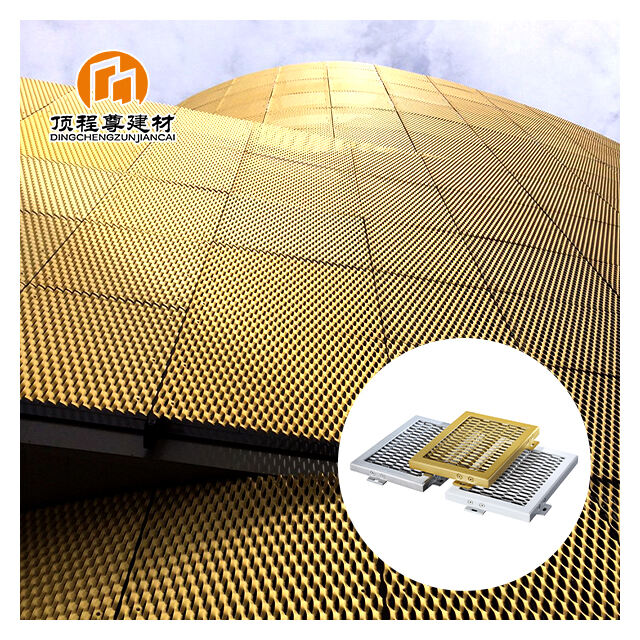

aluminum honeycomb panels for sale

Aluminum honeycomb panels represent a cutting-edge architectural and industrial material that combines lightweight construction with exceptional structural integrity. These panels consist of a hexagonal cell core structure sandwiched between two aluminum face sheets, creating a remarkably strong yet lightweight composite material. The panels are manufactured through an advanced bonding process that ensures superior adhesion between the core and face sheets, resulting in a unified structure capable of withstanding significant loads and environmental stresses. The honeycomb core design maximizes strength while minimizing material usage, making these panels an economically efficient choice for various applications. These versatile panels offer excellent flatness, impact resistance, and thermal insulation properties, making them ideal for both interior and exterior applications. The panels demonstrate remarkable resistance to corrosion and weather elements, ensuring long-term durability in diverse environments. They can be customized in terms of cell size, thickness, and surface finish to meet specific project requirements, whether for architectural facades, interior partitions, or industrial applications. The panels also exhibit superior sound dampening properties and fire resistance, contributing to their widespread adoption in modern construction and design projects.