Sustainable construction practices have become essential in modern architecture, with builders and designers increasingly seeking materials that minimize environmental impact while maximizing performance. Metal ceilings represent a significant advancement in green building technology, offering numerous ecological benefits that align with contemporary sustainability goals. These innovative ceiling systems provide exceptional durability, energy efficiency, and recyclability, making them an ideal choice for environmentally conscious construction projects. The integration of metal ceilings into building designs supports LEED certification requirements and helps reduce the overall carbon footprint of commercial and residential structures.

Environmental Impact and Sustainability Features

Recyclable Materials and Circular Economy

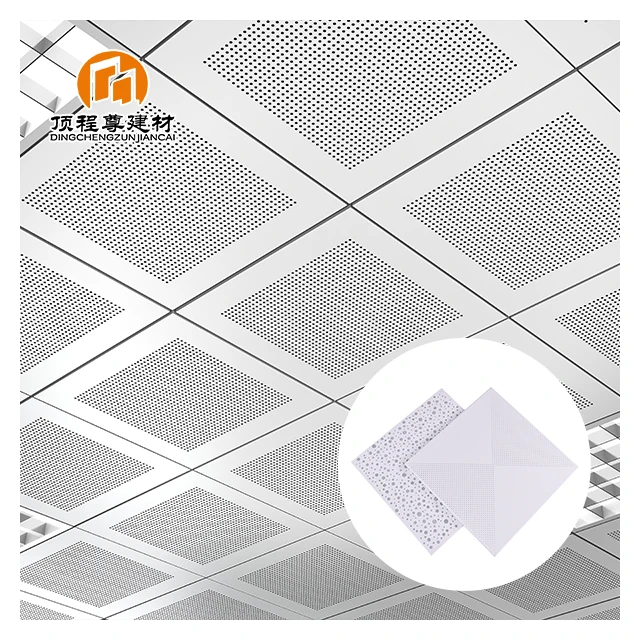

The aluminum and steel components used in metal ceilings contribute significantly to circular economy principles through their infinite recyclability. Unlike traditional ceiling materials that often end up in landfills, metal ceiling tiles can be completely recycled without losing their structural integrity or performance characteristics. This recyclability extends the material lifecycle indefinitely, reducing the need for virgin raw materials and minimizing waste generation. Manufacturing processes for recycled metal require substantially less energy compared to producing new materials from ore, resulting in reduced greenhouse gas emissions.

Modern metal ceiling systems incorporate high percentages of post-consumer and post-industrial recycled content, often exceeding 70% recycled materials. This composition supports green building rating systems and helps projects achieve sustainability certifications. The closed-loop recycling process for metals ensures that today's ceiling installations can become tomorrow's building materials, creating a sustainable cycle that benefits both the construction industry and the environment.

Low Volatile Organic Compound Emissions

Indoor air quality represents a critical factor in green building design, and metal ceilings excel in maintaining healthy interior environments. These systems emit virtually no volatile organic compounds (VOCs), unlike many traditional ceiling materials that can release harmful chemicals for years after installation. The absence of organic binders, adhesives, or composite materials in metal ceiling construction eliminates common sources of indoor air pollution.

The non-porous surface of metal ceilings prevents the accumulation of dust, allergens, and microbial growth, further contributing to superior indoor air quality. This characteristic proves particularly valuable in healthcare facilities, educational institutions, and commercial spaces where occupant health takes priority. The antimicrobial properties of certain metal finishes provide additional protection against bacteria and fungi without requiring chemical treatments.

Energy Efficiency and Thermal Performance

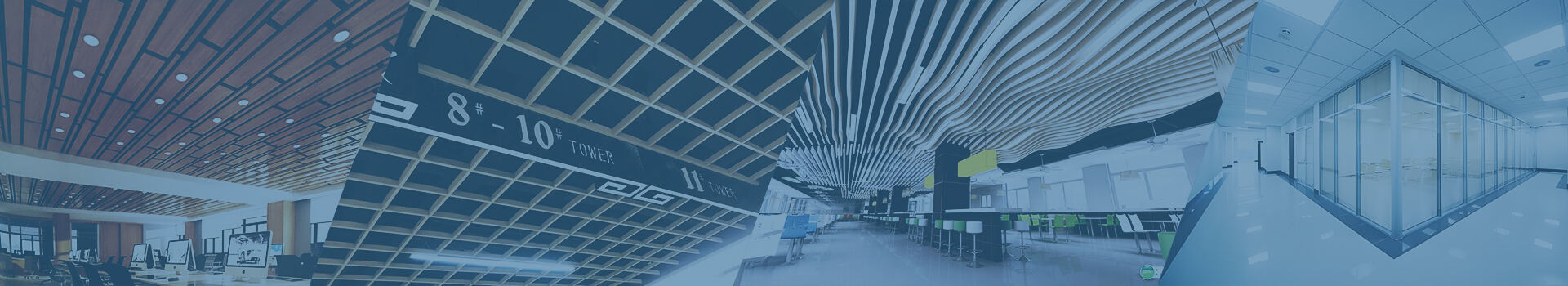

Reflective Properties and Light Management

Metal ceiling surfaces possess excellent light reflective qualities that significantly improve interior illumination efficiency. High-quality finishes can achieve reflectance values exceeding 80%, reducing the artificial lighting requirements throughout the day. This enhanced light distribution minimizes energy consumption for electrical lighting systems while creating more comfortable and productive interior environments.

Strategic implementation of reflective metal ceilings can reduce lighting energy costs by up to 20% in commercial applications. The uniform light distribution achieved through metal ceiling systems eliminates hot spots and shadows, providing consistent illumination across large spaces. These properties support daylight harvesting strategies and automated lighting controls that further optimize energy performance.

Thermal Regulation and HVAC Efficiency

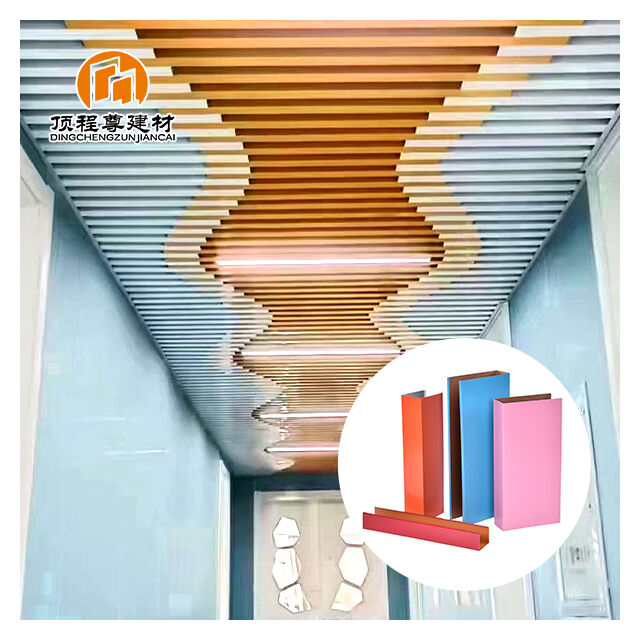

The thermal properties of metal ceilings contribute to improved HVAC system efficiency through enhanced heat transfer and air circulation patterns. Metal's high thermal conductivity allows for more responsive temperature control, enabling HVAC systems to operate more efficiently. Perforated metal ceiling designs facilitate superior air movement, reducing the energy required for ventilation and climate control.

Radiant cooling systems integrated with metal ceilings provide exceptional energy savings compared to traditional forced-air systems. The metal surface acts as an effective heat sink, absorbing and dissipating thermal energy throughout the space. This passive cooling approach can reduce HVAC energy consumption by 15-30% while maintaining optimal comfort levels for building occupants.

Durability and Lifecycle Benefits

Extended Service Life and Maintenance Reduction

Metal ceilings demonstrate exceptional longevity, often lasting 50 years or more without significant degradation. This extended service life reduces the frequency of replacement cycles, minimizing material consumption and construction waste over the building's lifetime. The corrosion-resistant coatings and treatments applied to modern metal ceiling systems provide protection against moisture, chemicals, and environmental factors that typically compromise other ceiling materials.

Maintenance requirements for metal ceilings remain minimal throughout their service life, requiring only periodic cleaning to maintain appearance and performance. The non-porous surface resists staining and discoloration, eliminating the need for frequent painting or refinishing. This low-maintenance characteristic reduces the use of cleaning chemicals and maintenance materials, contributing to overall environmental benefits.

Resistance to Environmental Factors

The inherent properties of metal ceiling materials provide excellent resistance to fire, moisture, and seismic activity. Fire-resistant characteristics eliminate the need for additional flame-retardant treatments that may contain harmful chemicals. Moisture resistance prevents mold and mildew growth, maintaining healthy indoor environments without requiring antimicrobial treatments.

Seismic performance of metal ceilings exceeds that of many alternative materials, reducing the risk of damage during earthquakes and minimizing repair requirements. This resilience contributes to building longevity and reduces the environmental impact associated with disaster recovery and reconstruction. The lightweight nature of metal ceiling systems also reduces structural loading, allowing for more efficient building designs.

Manufacturing and Installation Efficiency

Precision Manufacturing and Waste Reduction

Advanced manufacturing processes for metal ceilings minimize material waste through precise cutting and forming techniques. Computer-controlled production systems optimize material usage, reducing scrap generation and maximizing yield from raw materials. The modular design of metal ceiling systems allows for efficient packaging and transportation, reducing shipping-related environmental impacts.

Local and regional manufacturing capabilities for metal ceilings reduce transportation distances and associated carbon emissions. Many manufacturers operate multiple facilities to serve regional markets, minimizing the environmental impact of product distribution. The standardized dimensions and connection systems enable efficient inventory management and reduce overproduction waste.

Installation Speed and Construction Impact

The clip-in installation system common to metal ceilings significantly reduces construction time and associated environmental impacts. Faster installation reduces on-site energy consumption, equipment usage, and construction vehicle emissions. The precision-manufactured components require minimal field modification, reducing construction waste and improving installation quality.

Demountable metal ceiling systems support building flexibility and adaptability, allowing for easy reconfiguration without material waste. This adaptability extends building useful life and reduces the need for major renovations. The ability to access building systems through removable ceiling panels facilitates maintenance and upgrades, improving overall building performance over time.

Integration with Green Building Standards

LEED Certification Contributions

Metal ceilings contribute to multiple LEED credit categories, including Materials and Resources, Indoor Environmental Quality, and Energy and Atmosphere. The high recycled content of metal ceiling products supports MR Credit 4 requirements, while low emissions contribute to EQ Credit 4.1. The energy efficiency benefits can contribute to EA credits related to lighting and HVAC optimization.

Regional material sourcing opportunities for metal ceilings support MR Credit 5, reducing transportation environmental impacts. The durability and longevity of metal ceiling systems align with LEED's emphasis on building lifecycle performance and resource conservation. Documentation and certification processes for metal ceiling products facilitate LEED submission requirements and project tracking.

Other Green Building Rating Systems

Metal ceilings contribute to various international green building standards, including BREEAM, Green Star, and CASBEE. The universal sustainability characteristics of metal ceiling systems translate well across different rating frameworks and regional requirements. The availability of environmental product declarations (EPDs) and health product declarations (HPDs) supports documentation requirements for multiple certification programs.

The performance characteristics of metal ceilings align with emerging sustainability standards focused on circular economy principles and carbon reduction. Future developments in green building certification are likely to further recognize the environmental benefits of metal ceiling systems. The transparency of material composition and manufacturing processes supports evolving disclosure requirements in sustainable construction.

FAQ

How do metal ceilings compare to other ceiling materials in terms of environmental impact

Metal ceilings significantly outperform traditional materials like mineral fiber, gypsum, and wood in several environmental categories. They offer complete recyclability, zero VOC emissions, and exceptional durability that can exceed 50 years. Unlike mineral fiber ceilings that often contain formaldehyde binders or wood products that may require chemical treatments, metal ceilings maintain their performance without harmful additives. The energy required to recycle metal is substantially lower than producing new materials, making metal ceilings a superior choice for sustainable construction projects.

Can metal ceilings contribute to LEED points and green building certifications

Yes, metal ceilings can contribute to multiple LEED credit categories and other green building certifications. They typically qualify for Materials and Resources credits due to high recycled content, Indoor Environmental Quality credits for low emissions, and potentially Energy and Atmosphere credits through improved lighting efficiency. Many metal ceiling manufacturers provide detailed documentation including environmental product declarations and health product declarations to support certification submissions. The specific point contribution varies by project and product selection, but metal ceilings consistently support sustainable building goals.

What maintenance requirements do metal ceilings have compared to traditional options

Metal ceilings require significantly less maintenance than traditional ceiling materials throughout their service life. The non-porous surface resists staining, moisture damage, and microbial growth, requiring only periodic cleaning with standard maintenance practices. Unlike mineral fiber or gypsum ceilings that may need replacement due to water damage or sagging, metal ceilings maintain their structural integrity and appearance for decades. This reduced maintenance requirement translates to lower lifecycle costs and reduced environmental impact from cleaning chemicals and replacement materials.

Are there specific types of metal ceilings that offer the greatest environmental benefits

Aluminum ceilings generally offer the greatest environmental benefits due to aluminum's infinite recyclability and lightweight properties. High-recycled-content products with powder-coated finishes provide optimal sustainability performance while maintaining durability and appearance. Perforated designs can enhance acoustic performance and air circulation, contributing to energy efficiency. Products manufactured locally or regionally offer additional environmental advantages through reduced transportation impacts. When selecting metal ceilings for green building projects, consider certified products with third-party verification of environmental claims and comprehensive lifecycle documentation.

Table of Contents

- Environmental Impact and Sustainability Features

- Energy Efficiency and Thermal Performance

- Durability and Lifecycle Benefits

- Manufacturing and Installation Efficiency

- Integration with Green Building Standards

-

FAQ

- How do metal ceilings compare to other ceiling materials in terms of environmental impact

- Can metal ceilings contribute to LEED points and green building certifications

- What maintenance requirements do metal ceilings have compared to traditional options

- Are there specific types of metal ceilings that offer the greatest environmental benefits