aluminum honeycomb core panels

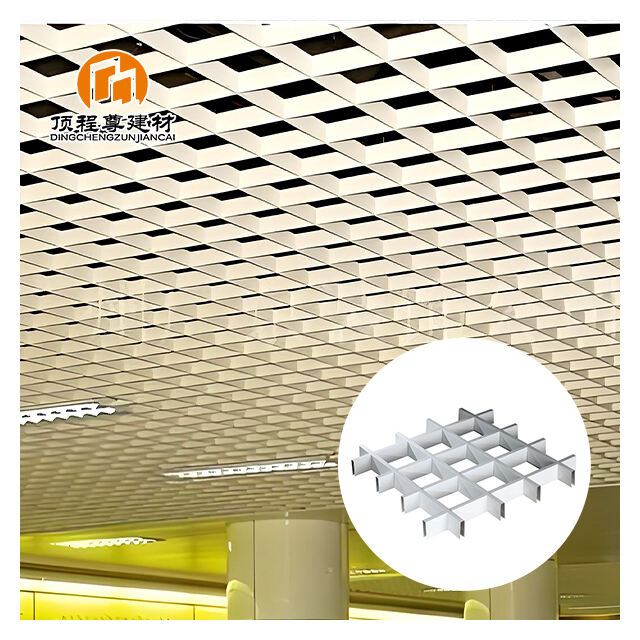

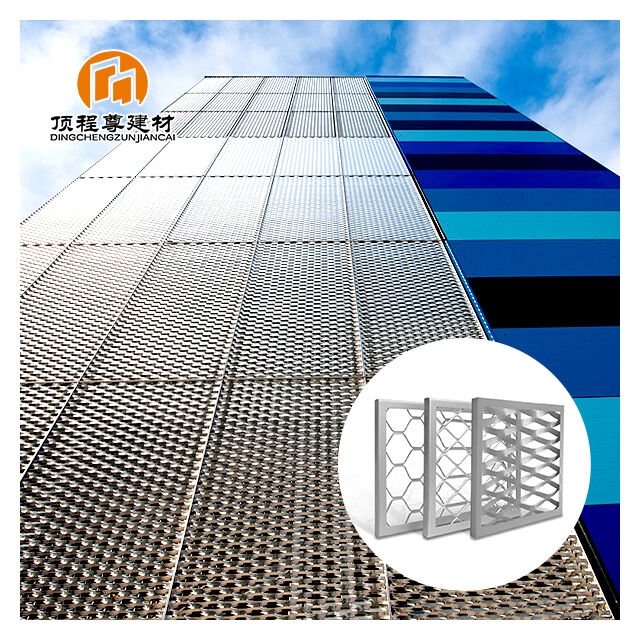

Aluminum honeycomb core panels represent a revolutionary advancement in lightweight structural materials, combining exceptional strength with minimal weight. These panels consist of a hexagonal cell structure sandwiched between two aluminum face sheets, creating a remarkably robust yet lightweight composite material. The honeycomb core, formed through a precision manufacturing process, provides superior compression strength and shear resistance while maintaining minimal density. These panels excel in applications requiring high strength-to-weight ratios, making them invaluable in aerospace, architecture, and transportation industries. The unique hexagonal structure allows for optimal distribution of forces across the panel surface, while the aluminum composition ensures excellent durability and corrosion resistance. The panels can be customized in terms of cell size, thickness, and density to meet specific project requirements. Their thermal and acoustic insulation properties, combined with fire resistance characteristics, make them particularly suitable for building facades, interior partitions, and industrial applications. The panels also demonstrate remarkable flatness and dimensional stability under varying environmental conditions, ensuring consistent performance throughout their service life.