In environments where safety and durability are non-negotiable, aluminum ceilings emerge as the ultimate safeguard. Combining Class A fire resistance with unmatched moisture protection, these panels are engineered to thrive in extreme conditions—from steamy swimming pools to hurricane-prone coastal facilities. Let’s explore why architects and facility managers trust aluminum ceilings to protect lives, assets, and structural integrity.

1. Class A Fire Resistance: Uncompromised Safety

When fire breaks out, every second counts. Traditional ceiling materials like PVC or mineral fiber can fuel flames or release lethal smoke.

Aluminum ceilings, however, are designed to resist ignition and slow fire spread:

High Melting Point (660°C/1220°F): Aluminum softens at 660°C but doesn’t combust, buying critical time for evacuation and firefighting.

Zero Toxic Emissions: Unlike plastic-based materials, aluminum won’t release cyanide, dioxins, or other poisonous gases when exposed to heat.

ASTM E84 Certification: Tested to achieve a flame spread index ≤25 and smoke density ≤450—exceeding requirements for Class A fire-rated assemblies.

Real-World Impact:

In a 2022 retrofit of a Chicago high-rise, aluminum ceilings helped the building achieve NFPA 101 Life Safety Code compliance, reducing insurance premiums by 18%.

2. Superior Moisture & Corrosion Resistance

Humidity, salt spray, and chemical exposure destroy conventional ceilings. Aluminum panels, with advanced surface engineering, defy degradation:

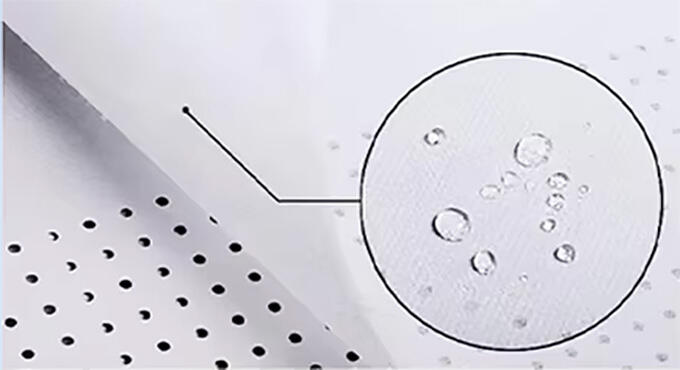

Anodized Defense Layer: Electrochemical anodizing creates a micro-crystalline oxide barrier, blocking water penetration even in 95% RH environments.

Salt Spray Survival: Tested to ASTM B117 standards, our panels withstand 1,000+ hours of salt fog—equivalent to 50 years in coastal Florida.

Anti-Microbial Options: Optional silver-ion coatings inhibit mold and bacteria growth, crucial for sterile environments like hospitals.

Case Study: Miami Beach Hospital

After replacing vinyl ceilings with aluminum panels in their ICU wing:

✔️ Humidity-related maintenance calls dropped 92%

✔️ Ceiling lifespan extended from 5 to 25+ years

3. Applications: Where Aluminum Ceilings Shine

A. Healthcare Facilities

Fire Safety: Meets NFPA 99 Health Care Facilities Code for fire resistance.

Sterility: Non-porous surfaces resist bloodborne pathogens and chemical disinfectants.

B. Laboratories & Cleanrooms

Corrosion Resistance: Withstands exposure to acids, solvents, and volatile organic compounds (VOCs).

Seamless Integration: Compatible with HEPA filtration and positive pressure systems.

C. Coastal & Underground Structures

Hurricane Zones: 6063-T5 alloy panels endure wind speeds up to 150 mph.

Parking Garages: Resists exhaust fumes and de-icing salts.

4. Cost-Saving Durability: By the Numbers

Metric Aluminum Ceiling PVC Ceiling

Lifespan 25+ years 8-12 years

Fire Retrofit Cost $0.50/sf $2.75/sf*

Annual Maintenance $0.15/sf $0.80/sf

Source: 2023 Facility Maintenance Report

5. Case Studies: Proven Performance

Project 1: Texas Chemical Plant

Challenge: Acidic fumes degraded steel-reinforced ceilings in 3 years.

Solution: Installed 12,000 sf of 2mm-thick AA3105 aluminum panels with PTFE coating.

Result: Zero corrosion after 7 years; ROI achieved in 18 months.

Project 2: Dubai Marine Museum

Challenge: Saltwater air caused ceiling collapse within 5 years.

Solution: Salt-spray-certified aluminum ceilings with concealed drainage channels.

Result: Maintenance costs reduced by AED 120,000/year.

Your Next Step: Certification & Compliance Made Easy

Don’t gamble with safety certifications. Our aluminum ceilings come with:

✅ UL Fire Resistance Certificate

✅ ISO 9227 Corrosion Test Reports

✅ 10-Year Performance Warranty