Meta Description: Discover how aluminum ceilings slash lifetime costs by 40% vs traditional materials. UV-resistant, low maintenance, and built to last 25+ years. Calculate your savings now!

In an era of rising construction costs and sustainability mandates, aluminum ceilings are revolutionizing budget planning. Beyond their sleek aesthetics lies a hidden superpower: 40% lower total ownership costs over 10 years compared to PVC or gypsum alternatives. Let’s dissect how these systems deliver decades of savings through durability, minimal upkeep, and smart design.

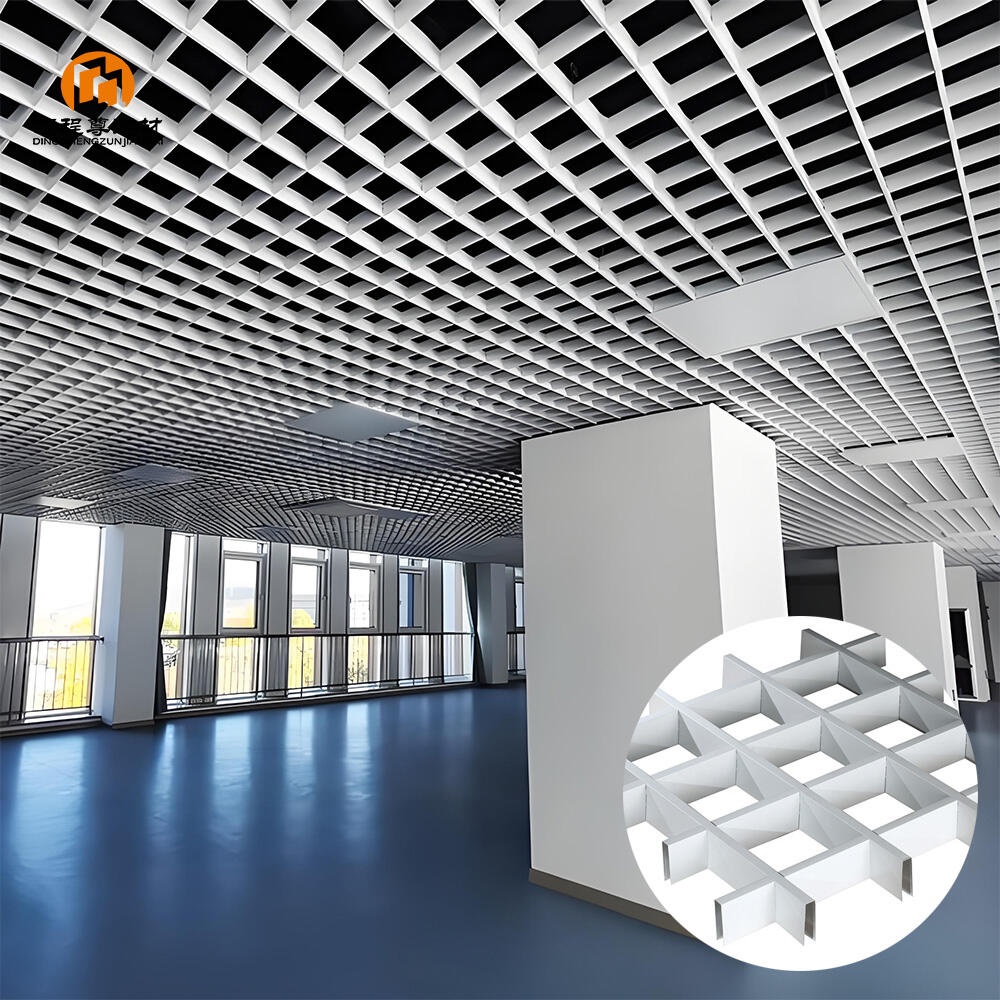

1. Decades of Durability: Built to Outlast

Aluminum ceilings aren’t just long-lasting—they’re virtually ageless. Here’s why:

A. Warranty-Backed Longevity

15-25 Year Warranties: Industry-leading coverage against corrosion, warping, and UV degradation.

UV-Resistant Coatings: Outdoor-grade panels retain 95% color stability after 10,000 hours of ASTM G154 UV testing (equivalent to 15 years in Arizona sun).

B. Corrosion Immunity

Salt Spray Survival: 3,000-hour ASTM B117 compliance vs PVC’s 500-hour limit.

Chemical Resistance: Withstand pH 3–11 cleaners, ideal for hospitals and labs.

C. Structural Integrity

Zero sagging in 95% humidity (tested per ASTM D3273) vs gypsum’s 60% humidity limit.

Thermal expansion coefficient of 23 µm/m·K prevents warping (-40°C to 80°C).

2. Minimal Maintenance, Maximum Savings

Aluminum’s smart engineering slashes operational costs:

A. Self-Cleaning Surfaces

Anti-Static Nanocoatings: Reduce dust adhesion by 70%, cutting cleaning frequency from weekly to quarterly.

Hospital-Grade Cleanability: Wipeable with ethanol/bleach solutions (tested to ISO 22196 antimicrobial standards).

B. Modular Repairs, Zero Downtime

Replace single 600x600mm panels in 5 minutes vs’s 4-hour plaster/dry cycle.

Hidden Access Panels: Integrate maintenance hatches without visual disruption.

C. Energy Efficiency Boost

High-reflectivity finishes (85% light reflectance) reduce lighting loads by 20-30%.

Thermal breaks lower HVAC costs in climate-controlled spaces.

3. ROI Analysis: Aluminum vs Traditional Ceilings

Cost Factor Aluminum Ceiling PVC Ceiling Gypsum Ceiling

Initial Install $8.50/sq. ft $6.20/sq. ft $4.80/sq.ft

10-Year Maintenance $1.20/sq. ft $7.80/sq. ft $9.50/sq.ft

Replacement Cycles 0 (25-year lifespan) 2x full replacements 3x full replacements

Total 10-Year Cost $9.70/sq. ft $21.80/sq. ft (+125%) $33.30/sq. ft (+243%)

Source: 2024 NIST Building Lifecycle Cost Report

4. Case Studies: Real-World Savings

Project 1: Las Vegas Convention Center Expansion

Challenge: Reduce 500,000 sq. ft hall’s lifecycle costs under desert extremes.

Solution: Installed 1.2mm UV-resistant aluminum panels with 30% perforation for HVAC integration.

Results:

$2.1M saved over 10 years vs original gypsum plan.

Zero ceiling maintenance during 2019-2023 CES shows.

Project 2: Singapore High-Rise Retrofits

Challenge: Cut 30-tower complex’s maintenance budget post-COVID.

Solution: Replaced mold-damaged PVC with anti-microbial aluminum ceilings.

Results:

78% drop in ceiling-related work orders.

Achieved BCA Green Mark Platinum with 95% recycled content.