Modern construction projects increasingly rely on advanced building materials that combine aesthetic appeal with functional performance. Among these materials, aluminum cladding panels have emerged as a preferred choice for architects, contractors, and building owners seeking durable, versatile, and cost-effective exterior solutions. These innovative panels offer a comprehensive approach to building envelope design, providing protection against environmental elements while enhancing the visual appeal of commercial and residential structures.

The construction industry has witnessed significant evolution in exterior cladding technologies over the past decades. Traditional materials like brick, stone, and wood, while still valuable, often present limitations in terms of installation complexity, maintenance requirements, and design flexibility. Aluminum cladding panels address these challenges by offering superior performance characteristics that meet the demanding requirements of contemporary architecture. Their lightweight nature, combined with exceptional strength-to-weight ratios, makes them ideal for both new construction and renovation projects.

Understanding the comprehensive benefits of aluminum cladding panels requires examining their performance across multiple dimensions including structural integrity, environmental resistance, aesthetic versatility, and long-term economic value. These panels represent a sophisticated engineering solution that balances form and function, delivering measurable advantages that extend throughout the building's lifecycle. From initial installation through decades of service, aluminum cladding panels consistently demonstrate their value proposition across diverse construction applications.

Superior Durability and Weather Resistance

Corrosion Resistance Properties

Aluminum naturally forms a protective oxide layer when exposed to air, creating an inherent barrier against corrosion that surpasses many traditional cladding materials. This self-protecting characteristic ensures that aluminum cladding panels maintain their structural integrity even in harsh environmental conditions including coastal areas with high salt content, industrial zones with chemical exposure, and regions experiencing extreme temperature fluctuations. The oxide layer continuously regenerates itself, providing ongoing protection without requiring additional treatments or coatings.

Advanced surface treatments further enhance the corrosion resistance of aluminum cladding panels through processes like anodizing and powder coating. These treatments create additional protective barriers that extend the material's lifespan while offering expanded color and finish options. The combination of natural oxide formation and engineered surface treatments results in cladding systems that can withstand decades of exposure to UV radiation, moisture, and atmospheric pollutants without significant degradation.

Structural Stability Under Environmental Stress

The mechanical properties of aluminum cladding panels provide exceptional resistance to wind loads, thermal expansion, and seismic activity. Their high strength-to-weight ratio allows for secure attachment systems that distribute loads effectively across the building structure while minimizing additional dead weight. This characteristic proves particularly valuable in high-rise construction where wind resistance becomes a critical design factor.

Thermal stability represents another crucial advantage of aluminum cladding panels in varying climate conditions. The material's coefficient of thermal expansion allows for predictable movement that can be accommodated through proper joint design and installation techniques. Unlike some materials that become brittle in cold temperatures or soften in extreme heat, aluminum maintains consistent performance characteristics across wide temperature ranges, ensuring reliable protection and appearance throughout seasonal variations.

Energy Efficiency and Thermal Performance

Insulation Integration Capabilities

Modern aluminum cladding panels can be configured with integrated insulation systems that significantly improve building envelope thermal performance. These composite systems incorporate high-performance insulation materials between the exterior aluminum face and interior backing, creating continuous insulation that reduces thermal bridging and enhances overall energy efficiency. The result is improved indoor comfort and reduced heating and cooling costs throughout the building's operational life.

The versatility of aluminum cladding panels allows for various insulation configurations including rigid foam cores, mineral wool assemblies, and aerogel-enhanced systems. Each configuration can be tailored to specific climate zones and building performance requirements, enabling architects and engineers to optimize thermal performance while maintaining design flexibility. The precision manufacturing capabilities of aluminum panels ensure consistent insulation thickness and thermal performance across the entire building envelope.

Solar Reflectance and Heat Management

Properly finished aluminum cladding panels demonstrate excellent solar reflectance properties that reduce heat absorption and lower cooling loads during warm weather periods. Light-colored and specially formulated finishes can reflect significant portions of solar radiation, preventing heat buildup within the building envelope and reducing the burden on mechanical cooling systems. This characteristic becomes increasingly important as energy codes become more stringent and building owners seek to minimize operational costs.

The thermal mass characteristics of aluminum cladding panels also contribute to energy efficiency through their rapid response to temperature changes. Unlike materials with high thermal mass that store and slowly release heat, aluminum responds quickly to ambient conditions, allowing building systems to more effectively control interior temperatures. This responsiveness complements modern building automation systems that rely on precise environmental control to optimize energy consumption.

Design Flexibility and Aesthetic Appeal

Finish Options and Color Variety

The aesthetic possibilities offered by aluminum cladding panels span an impressive range of colors, textures, and finishes that accommodate virtually any architectural vision. Powder coating technologies enable precise color matching and custom formulations that maintain their appearance for decades without fading or chalking. From subtle neutrals that complement natural surroundings to bold accent colors that create striking architectural statements, aluminum panels provide designers with unlimited creative options.

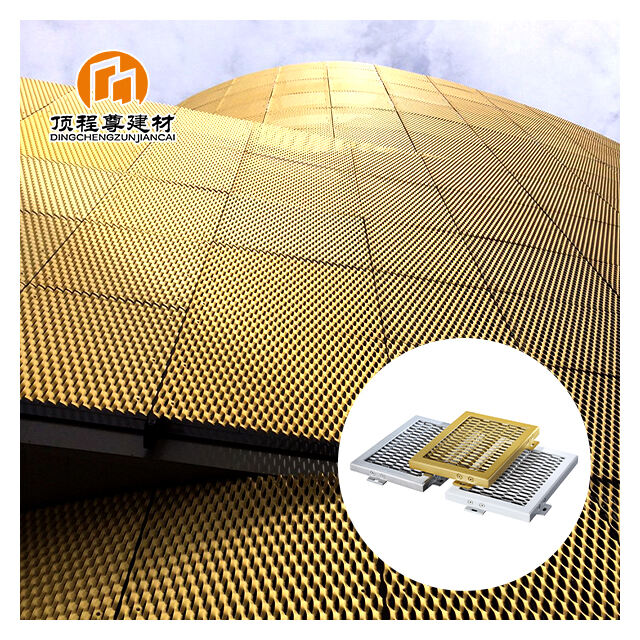

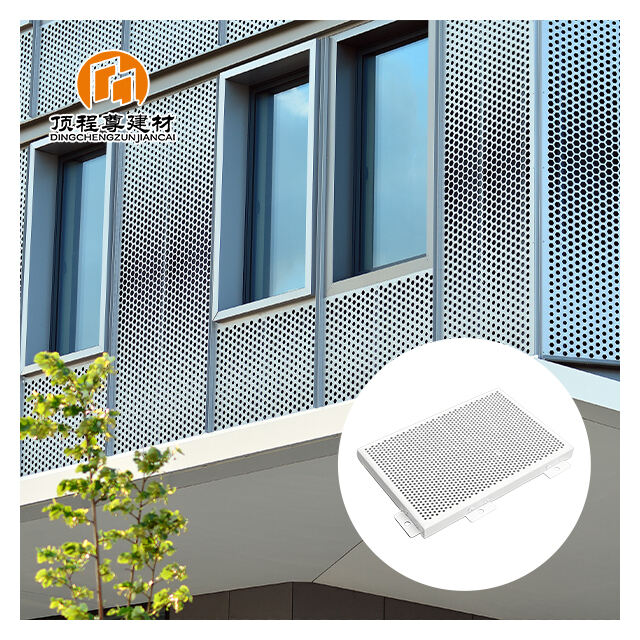

Textural variations add another dimension to aluminum cladding panel aesthetics through techniques like brushing, embossing, and perforation. These surface treatments can simulate natural materials like wood grain or stone texture while retaining all the performance advantages of aluminum. The ability to combine different textures and colors within a single project creates opportunities for sophisticated facade compositions that respond to light, shadow, and viewing angles throughout the day.

Installation Versatility and System Integration

The lightweight nature and precision manufacturing of aluminum cladding panels facilitate diverse installation approaches that can accommodate complex architectural geometries and challenging site conditions. Standard rectangular panels work effectively for straightforward applications, while custom-formed panels enable curved surfaces, angular transitions, and unique architectural features. This versatility extends to integration with other building systems including windows, doors, and mechanical equipment.

Modular installation systems for aluminum cladding panels streamline construction schedules while ensuring consistent quality and appearance. Prefabricated panel assemblies can be manufactured off-site with integrated mounting systems, reducing field installation time and weather-related delays. The precision fit and finish possible with factory-manufactured panels often exceeds what can be achieved through field assembly, resulting in superior visual quality and long-term performance.

Cost-Effectiveness and Long-Term Value

Initial Installation Economics

While the upfront material cost of aluminum cladding panels may exceed some traditional alternatives, the total installation cost often proves competitive due to reduced labor requirements and faster installation schedules. The lightweight nature of aluminum panels minimizes structural support requirements, potentially reducing foundation and framing costs. Additionally, the precision manufacturing and modular design of these panels streamline the installation process, reducing labor hours and associated costs.

The scheduling advantages of aluminum cladding panel installation translate directly into economic benefits through reduced construction financing costs and earlier building occupancy. Weather-resistant installation procedures allow work to continue under conditions that might halt other cladding systems, maintaining project schedules and avoiding costly delays. These factors combine to create favorable project economics that often offset higher material costs.

Maintenance Requirements and Lifecycle Costs

The minimal maintenance requirements of aluminum cladding panels represent a significant long-term economic advantage compared to materials requiring regular painting, sealing, or replacement. Routine cleaning with standard building maintenance procedures maintains appearance and performance for decades without specialized treatments or costly interventions. This characteristic proves particularly valuable for buildings in locations where maintenance access is difficult or expensive.

Lifecycle cost analysis consistently demonstrates the economic advantages of aluminum cladding panels over extended ownership periods. While initial costs may be higher than some alternatives, the combination of minimal maintenance, exceptional durability, and energy efficiency benefits creates compelling return on investment calculations. Building owners increasingly recognize these long-term value propositions as essential factors in material selection decisions, particularly for commercial and institutional projects where operational costs significantly impact overall profitability.

Environmental Sustainability Benefits

Recycling and Material Recovery

Aluminum ranks among the most recyclable construction materials, with the ability to be reprocessed indefinitely without loss of material properties. This characteristic aligns with growing emphasis on circular economy principles and sustainable construction practices. At the end of their service life, aluminum cladding panels can be completely recovered and remanufactured into new products, minimizing waste and reducing demand for virgin materials.

The energy required to recycle aluminum represents only a fraction of that needed for primary production, making recycled aluminum one of the most energy-efficient materials available for construction applications. This efficiency translates into reduced environmental impact and lower embodied energy for buildings incorporating recycled aluminum content. Many manufacturers now offer aluminum cladding panels with significant recycled content, further enhancing their environmental credentials without compromising performance.

Building Performance and Operational Efficiency

The energy efficiency contributions of aluminum cladding panels extend beyond their recycling benefits to include operational energy savings throughout the building's life. Improved thermal performance reduces heating and cooling energy consumption, while durable finishes eliminate the need for periodic repainting that involves volatile organic compounds and disposal of degraded materials. These operational benefits accumulate over decades of building use, creating substantial environmental advantages.

Life cycle assessment studies consistently demonstrate the environmental advantages of aluminum cladding panels when evaluated across their complete service life. The combination of manufacturing efficiency, transportation advantages due to light weight, installation benefits, operational energy savings, and end-of-life recyclability creates a comprehensive sustainability profile that supports green building certification programs and corporate environmental responsibility goals.

FAQ

How long do aluminum cladding panels typically last

High-quality aluminum cladding panels with proper finishes can maintain their appearance and performance for 30-50 years or more with minimal maintenance. The natural corrosion resistance of aluminum, combined with advanced coating systems, ensures long-term durability even in challenging environmental conditions. Many manufacturers offer warranties extending 20-25 years, reflecting confidence in the material's longevity.

Can aluminum cladding panels be installed over existing building exteriors

Yes, aluminum cladding panels are frequently used in renovation projects where they can be installed over existing wall systems. Their lightweight nature minimizes structural loading concerns, while various mounting systems accommodate different substrate conditions. This application provides an effective way to update building appearance and improve energy performance without complete exterior reconstruction.

What fire resistance properties do aluminum cladding panels offer

Aluminum itself is non-combustible and will not contribute to fire spread, though the performance of complete panel systems depends on core materials and installation details. Many aluminum cladding panels incorporate fire-resistant core materials and are designed to meet specific fire safety codes. Proper specification and installation according to manufacturer guidelines ensure compliance with building safety requirements.

How do aluminum cladding panels perform in extreme weather conditions

Aluminum cladding panels demonstrate excellent performance across extreme weather conditions including high winds, temperature fluctuations, and moisture exposure. Their structural properties and installation systems are engineered to accommodate thermal movement and wind loads typical of their intended applications. Proper design and installation enable reliable performance in climates ranging from arctic conditions to tropical environments with high humidity and salt exposure.