Modern architectural designs demand innovative ceiling solutions that blend functionality with aesthetic appeal. The evolution of interior spaces has transformed how we approach overhead design elements, making customized false ceilings an essential component of contemporary construction. These sophisticated ceiling systems offer architects and designers unprecedented flexibility in creating unique environments that reflect current design trends while addressing practical building requirements. The integration of advanced materials and cutting-edge installation techniques has revolutionized the false ceiling industry, enabling professionals to achieve remarkable visual effects and improved building performance.

The strategic implementation of suspended ceiling systems addresses multiple architectural challenges while enhancing the overall design narrative. Professional installation teams work closely with architects to develop tailored solutions that complement specific project requirements, ensuring seamless integration with existing structural elements. This collaborative approach enables the creation of distinctive ceiling features that serve as focal points within modern interiors, contributing significantly to the spatial experience and user comfort.

Understanding Modern False Ceiling Design Principles

Architectural Integration Strategies

Successful customized false ceilings require careful consideration of architectural elements and spatial relationships. Design professionals must analyze the existing structure, lighting requirements, and mechanical systems to develop comprehensive ceiling solutions. The integration process involves detailed planning phases where architects evaluate ceiling heights, room proportions, and visual flow patterns to ensure optimal design outcomes.

Contemporary ceiling design emphasizes clean lines, geometric patterns, and innovative material applications that complement modern architectural aesthetics. The selection of appropriate ceiling systems depends on factors such as building function, environmental conditions, and maintenance requirements. Professional designers utilize advanced software tools to visualize ceiling configurations and optimize spatial relationships before implementation begins.

Material Selection Criteria

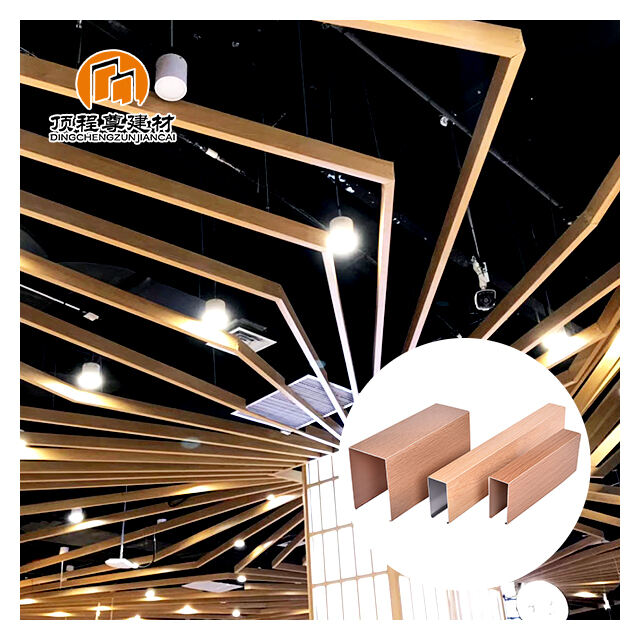

The choice of materials for customized false ceilings significantly impacts both performance and visual appeal. Modern ceiling systems incorporate diverse materials including aluminum panels, gypsum boards, mineral fiber tiles, and composite materials that offer varying degrees of durability, acoustic properties, and fire resistance. Each material category presents unique advantages and installation considerations that influence project outcomes.

Advanced material technologies have expanded design possibilities while improving functional performance characteristics. Manufacturers now offer specialized coatings, surface textures, and color options that enable designers to achieve specific aesthetic goals while maintaining required building standards. The evaluation of material properties includes factors such as thermal performance, moisture resistance, and long-term stability under varying environmental conditions.

Customization Techniques and Applications

Geometric Pattern Development

Creating distinctive geometric patterns requires sophisticated design methodologies and precise fabrication techniques. Designers develop custom patterns by analyzing spatial dimensions, lighting requirements, and acoustic performance goals to create unique ceiling configurations. The pattern development process involves iterative design phases where multiple concepts are evaluated for feasibility and visual impact.

Modern fabrication technologies enable the production of complex geometric forms that were previously difficult or impossible to achieve. Computer-controlled cutting systems and precision manufacturing processes allow for intricate pattern creation with consistent quality and dimensional accuracy. These advanced capabilities support the development of signature ceiling designs that distinguish architectural projects and enhance brand identity.

Lighting Integration Methods

Effective lighting integration represents a critical aspect of customized false ceilings that enhances both functionality and ambiance. Professional lighting designers work collaboratively with ceiling specialists to develop integrated systems that provide optimal illumination while maintaining design coherence. The planning process considers natural light patterns, artificial lighting requirements, and energy efficiency objectives.

Contemporary lighting integration techniques include concealed LED systems, recessed fixtures, and dynamic lighting controls that respond to changing environmental conditions. These advanced systems enable the creation of dramatic lighting effects while maintaining energy efficiency and reducing maintenance requirements. The coordination between ceiling structure and lighting components requires careful planning to ensure proper access for maintenance and system upgrades.

Installation and Technical Considerations

Structural Assessment Requirements

Proper installation of customized false ceilings begins with comprehensive structural assessment and engineering analysis. Professional installers evaluate existing building conditions, load-bearing capacity, and mechanical system integration requirements to develop appropriate installation strategies. This assessment phase identifies potential challenges and establishes safety protocols for successful project completion.

The structural evaluation process includes detailed measurements, material specifications, and coordination with other building trades to prevent conflicts during installation. Professional teams utilize specialized equipment and testing procedures to verify structural adequacy and ensure compliance with applicable building codes. This thorough approach minimizes project risks and ensures long-term performance reliability.

Quality Control Processes

Maintaining consistent quality throughout the installation process requires systematic quality control measures and regular inspection protocols. Professional installation teams implement standardized procedures that verify material quality, dimensional accuracy, and installation compliance at each project phase. These quality assurance measures help prevent defects and ensure project specifications are met consistently.

Advanced quality control systems include photographic documentation, measurement verification, and performance testing procedures that validate installation quality. Regular quality audits conducted by experienced supervisors help identify potential issues before they impact project schedules or performance outcomes. This proactive approach supports successful project delivery and client satisfaction.

Performance Optimization Strategies

Acoustic Performance Enhancement

Optimizing acoustic performance in customized false ceilings requires understanding of sound transmission principles and material selection strategies. Professional acoustic consultants work with ceiling designers to develop systems that address specific noise control requirements while maintaining aesthetic objectives. The acoustic design process considers room function, occupancy patterns, and environmental noise sources.

Modern acoustic ceiling systems incorporate specialized materials and installation techniques that enhance sound absorption and reduce noise transmission between spaces. These performance-oriented solutions enable architects to create comfortable environments that support productivity and well-being. The integration of acoustic performance features requires careful coordination between ceiling design and overall building systems.

Maintenance and Longevity Planning

Developing comprehensive maintenance strategies ensures long-term performance and appearance retention for customized false ceilings. Professional maintenance planning considers material characteristics, environmental exposure, and access requirements to establish appropriate service intervals and procedures. This forward-thinking approach helps protect investment value and maintains design integrity over time.

Regular maintenance protocols include cleaning procedures, inspection schedules, and replacement planning that address normal wear patterns and environmental effects. Professional maintenance teams utilize specialized equipment and techniques that preserve ceiling appearance while ensuring continued performance. The establishment of maintenance partnerships with qualified service providers supports ongoing system reliability and performance optimization.

FAQ

What factors influence the cost of customized false ceilings

The cost of customized false ceilings depends on several key factors including material selection, design complexity, installation requirements, and project scale. Premium materials such as specialized aluminum systems or custom-manufactured components typically command higher prices but offer superior performance and durability. Labor costs vary based on installation complexity, site conditions, and required specialized skills. Additional factors include engineering requirements, permit costs, and coordination with other building systems that may impact overall project expenses.

How do customized false ceilings impact building energy efficiency

Customized false ceilings can significantly enhance building energy efficiency through improved insulation, reduced air volume, and integrated lighting systems. The air space created above suspended ceilings provides additional insulation value that reduces heating and cooling loads. Properly designed ceiling systems can incorporate energy-efficient lighting and HVAC integration that optimizes building performance. The selection of reflective materials and strategic lighting placement can reduce artificial lighting requirements while maintaining adequate illumination levels.

What maintenance requirements should be expected with modern false ceiling systems

Modern false ceiling systems typically require minimal maintenance when properly installed and specified for their intended environment. Regular maintenance activities include periodic cleaning, inspection of support systems, and replacement of damaged components as needed. Access panels should be incorporated into designs to facilitate maintenance of mechanical systems located above ceiling areas. Professional maintenance schedules vary based on environmental conditions, occupancy patterns, and material specifications, but generally involve annual inspections and cleaning as needed.

How long does installation of customized false ceilings typically take

Installation timelines for customized false ceilings vary significantly based on project complexity, area size, and design specifications. Simple installations in standard commercial spaces may require only a few days, while complex custom designs with integrated systems can take several weeks to complete. Factors affecting installation duration include material delivery schedules, coordination with other trades, and site conditions. Professional contractors provide detailed scheduling that accounts for design complexity, quality control requirements, and building occupancy considerations to establish realistic project timelines.