Choosing the right ceiling solution for commercial and residential projects involves careful consideration of aesthetics, functionality, and budget constraints. The debate between traditional ceiling panels and open ceiling designs has intensified as architects and designers seek innovative ways to create visually appealing spaces while maintaining practical benefits. Modern construction projects increasingly favor solutions that combine visual impact with acoustic performance, making the selection process more complex than ever before.

The emergence of open cell aluminum ceiling systems has revolutionized how we approach interior design, particularly in restaurants, offices, and retail environments. These innovative solutions offer unique advantages that bridge the gap between completely open ceilings and traditional panel systems. Understanding the fundamental differences between these approaches helps property owners and designers make informed decisions that align with their project goals and requirements.

Understanding Open Cell Aluminum Ceiling Systems

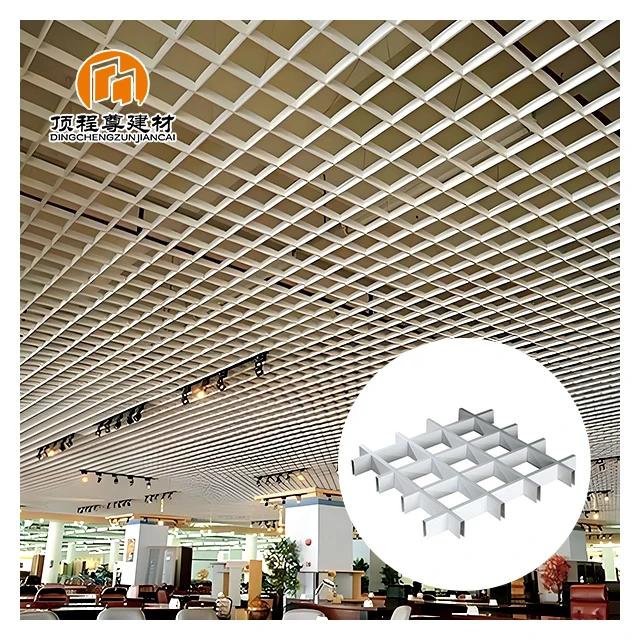

Design Principles and Construction

Open cell aluminum ceiling systems represent a sophisticated approach to interior design that combines the industrial aesthetic of exposed ceilings with the refined appearance of traditional panels. These systems feature a grid-like structure with strategically placed openings that allow air circulation while maintaining visual coherence. The aluminum construction provides exceptional durability and corrosion resistance, making it suitable for various environmental conditions including high-humidity spaces like restaurants and swimming pools.

The modular nature of open cell aluminum ceiling designs allows for unprecedented flexibility in installation and maintenance. Individual cells can be removed or replaced without disturbing the entire ceiling system, providing easy access to mechanical systems above while maintaining the overall aesthetic integrity. This feature proves particularly valuable in commercial environments where routine maintenance of HVAC, electrical, and plumbing systems is essential for operational continuity.

Acoustic Performance Benefits

One of the most significant advantages of open cell aluminum ceiling systems lies in their acoustic performance characteristics. The open structure allows sound waves to pass through the ceiling plane, reducing unwanted reflections and creating a more comfortable acoustic environment. This property makes them particularly suitable for restaurants, conference rooms, and other spaces where speech intelligibility and noise control are critical considerations.

The three-dimensional nature of open cell aluminum ceiling grids creates natural sound diffusion patterns that help eliminate problematic echo and reverberation. When combined with appropriate insulation materials above the ceiling plane, these systems can achieve excellent noise reduction coefficients while maintaining their distinctive visual appeal. Professional acoustic engineers often recommend open cell aluminum ceiling solutions for projects requiring both aesthetic innovation and superior sound management.

Traditional Ceiling Panel Advantages

Installation Simplicity and Cost Considerations

Traditional ceiling panels offer straightforward installation procedures that many contractors find familiar and efficient. The standardized mounting systems and proven installation techniques reduce labor costs and minimize project timeline uncertainty. For budget-conscious projects, conventional panel systems often present lower initial investment requirements compared to specialized open cell aluminum ceiling installations.

The widespread availability of traditional ceiling materials and accessories contributes to competitive pricing and reliable supply chains. Standard panel systems benefit from economies of scale in manufacturing and distribution, resulting in more predictable project costs. However, long-term maintenance considerations and replacement costs should be factored into total lifecycle calculations when comparing different ceiling approaches.

Thermal and Moisture Control

Solid ceiling panels provide superior thermal insulation properties compared to open systems, making them suitable for projects with strict energy efficiency requirements. The continuous barrier created by traditional panels helps maintain consistent indoor temperatures and reduces heating and cooling loads. This characteristic proves particularly valuable in climates with extreme temperature variations or in buildings with high energy performance standards.

Moisture control represents another area where traditional ceiling panels excel, particularly in applications requiring vapor barriers or humidity management. The sealed nature of panel systems prevents moisture migration and protects structural elements above the ceiling from potential damage. However, this same characteristic can create challenges in high-humidity environments where condensation management becomes critical.

Aesthetic Impact and Design Flexibility

Visual Appeal in Modern Architecture

Contemporary architectural trends increasingly favor transparency and visual connectivity between different building elements. Open cell aluminum ceiling systems align perfectly with these preferences by creating depth and dimension while maintaining clean, geometric patterns. The interplay of light and shadow through the grid structure adds visual interest without overwhelming other design elements in the space.

The metallic finish options available with open cell aluminum ceiling products allow designers to coordinate with other architectural metals throughout the project. Powder coating technologies enable custom color matching and specialized finishes that complement specific design themes. This flexibility extends beyond color to include various cell sizes and configurations that can be tailored to specific spatial requirements and design intentions.

Integration with Lighting and Mechanical Systems

Modern lighting design often benefits from the three-dimensional characteristics of open cell aluminum ceiling systems. LED strip lighting can be integrated within the grid structure to create dramatic uplighting effects, while recessed fixtures can be strategically positioned to provide focused task illumination. The open nature of these systems facilitates creative lighting solutions that would be difficult or impossible with traditional solid panels.

Mechanical system integration becomes significantly more flexible with open cell aluminum ceiling installations. HVAC diffusers can be mounted directly within the grid pattern, creating a seamless appearance that maintains the overall design aesthetic. The accessibility provided by removable cells allows for easy maintenance and modification of mechanical systems without major disruption to the occupied spaces below.

Performance in Specific Applications

Restaurant and Hospitality Environments

Restaurants present unique challenges for ceiling systems due to grease, moisture, and cleaning requirements. Open cell aluminum ceiling products excel in these environments due to their non-porous surfaces and chemical resistance. The open structure prevents grease buildup that commonly affects solid ceiling panels, while the aluminum material resists staining and maintains its appearance over time with minimal maintenance.

The acoustic benefits of open cell aluminum ceiling systems prove particularly valuable in restaurant applications where creating comfortable dining atmospheres requires careful sound management. The ability to control reverberation and reduce noise levels enhances the overall dining experience while allowing for flexible seating arrangements and varying occupancy levels throughout service periods.

Office and Commercial Spaces

Modern office design emphasizes flexibility and adaptability to accommodate changing workplace requirements. Open cell aluminum ceiling systems support these objectives by providing easy access to infrastructure while maintaining professional appearances. The modular nature of these systems allows for reconfiguration as office layouts evolve, providing long-term value and reducing renovation costs.

The light reflectance properties of aluminum surfaces contribute to improved illumination efficiency in office environments. When properly specified, open cell aluminum ceiling installations can reduce artificial lighting requirements by maximizing natural light distribution throughout the space. This characteristic supports sustainable building practices and can contribute to energy efficiency certifications and ratings.

Maintenance and Lifecycle Considerations

Cleaning and Upkeep Requirements

Maintenance requirements differ significantly between open cell aluminum ceiling systems and traditional panel installations. The open structure of aluminum grid systems allows for easier cleaning access and prevents the dust accumulation that commonly affects solid panels. Standard maintenance procedures typically involve periodic washing with appropriate cleaning solutions, which can be performed without removing individual components.

The corrosion resistance of aluminum materials ensures long-term appearance retention with minimal intervention. Unlike steel or other ferrous metals, aluminum naturally forms a protective oxide layer that prevents degradation in most indoor environments. This characteristic reduces maintenance costs and extends the useful life of open cell aluminum ceiling installations compared to other metallic ceiling systems.

Replacement and Modification Capabilities

The modular design of open cell aluminum ceiling systems provides exceptional flexibility for future modifications and upgrades. Individual cells or sections can be removed or replaced without affecting the entire installation, allowing for phased renovations or targeted repairs. This capability proves particularly valuable in commercial environments where business continuity during maintenance operations is essential.

Replacement parts availability and standardization ensure long-term support for open cell aluminum ceiling installations. Major manufacturers maintain extensive inventories of standard components, while custom configurations can be reproduced using documented specifications. This level of support provides confidence for property owners making long-term investments in ceiling systems.

FAQ

What are the main cost differences between open cell aluminum ceiling systems and traditional panels?

Initial installation costs for open cell aluminum ceiling systems typically run 15-30% higher than traditional panel systems due to specialized components and installation requirements. However, the long-term value proposition often favors aluminum systems due to reduced maintenance costs, longer lifespan, and superior performance characteristics. Total lifecycle costs should be evaluated over 15-20 year periods to accurately compare different ceiling approaches.

How do open cell aluminum ceiling systems perform in high-humidity environments?

Open cell aluminum ceiling products excel in high-humidity applications due to their corrosion resistance and ventilation properties. The open structure promotes air circulation that helps prevent condensation buildup, while the aluminum material resists moisture-related degradation. These characteristics make them particularly suitable for swimming pools, commercial kitchens, and coastal environments where traditional ceiling materials often fail prematurely.

Can existing traditional ceiling installations be converted to open cell aluminum ceiling systems?

Conversion from traditional panel systems to open cell aluminum ceiling installations is typically feasible but requires careful structural evaluation. The existing suspension system may need reinforcement or modification to accommodate the different load distribution patterns. Professional assessment by qualified contractors or structural engineers is recommended to ensure proper integration and code compliance during conversion projects.

What fire safety considerations apply to open cell aluminum ceiling installations?

Open cell aluminum ceiling systems generally provide superior fire performance compared to traditional panel materials due to the non-combustible nature of aluminum. The open structure allows sprinkler systems to operate more effectively, while the metal construction maintains structural integrity at elevated temperatures. Most installations easily meet or exceed building code fire safety requirements, though specific project conditions should always be verified with local authorities.

Table of Contents

- Understanding Open Cell Aluminum Ceiling Systems

- Traditional Ceiling Panel Advantages

- Aesthetic Impact and Design Flexibility

- Performance in Specific Applications

- Maintenance and Lifecycle Considerations

-

FAQ

- What are the main cost differences between open cell aluminum ceiling systems and traditional panels?

- How do open cell aluminum ceiling systems perform in high-humidity environments?

- Can existing traditional ceiling installations be converted to open cell aluminum ceiling systems?

- What fire safety considerations apply to open cell aluminum ceiling installations?