Aluminum ceilings are widely adopted in commercial spaces, office buildings, and public venues due to their durability, ease of cleaning, and aesthetic appeal. However, when faced with numerous aluminum ceiling options, selecting products that are both corrosion-resistant and high-quality remains a top concern for many buyers, designers, and engineers.

This article outlines five core material selection secrets to help you quickly identify premium aluminum ceiling solutions, particularly suited for factory-direct procurement models

Tip 1: Select the Right Aluminum Alloy: Material Fundamentals Determine Performance

The corrosion resistance of aluminum ceiling panels largely depends on the inherent properties of the aluminum alloy itself. The primary alloys used in commercially available aluminum ceiling panels include:

·AA3003 Aluminum Alloy: Offers a balanced strength-to-corrosion resistance ratio, suitable for most indoor environments

·AA5005 Aluminum Alloy: Features higher strength and superior corrosion resistance, ideal for humid and coastal areas

Material Selection Tips: Prioritize high-quality aluminum alloy materials that have undergone anodizing or coating treatments, as this significantly enhances corrosion resistance.

Tip 2: Verify corrosion resistance and performance testing: Don’t just take the marketing claims at face value

Truly superior aluminum ceilings should undergo rigorous performance testing. Common tests include:

·Salt spray test - simulates corrosion resistance in harsh environments

·Humidity and heat test - evaluates water absorption and weather resistance

·Coating adhesion test - assesses the bond strength between coating and substrate

When purchasing, request third-party test reports or laboratory results to verify the authenticity and effectiveness of corrosion resistance

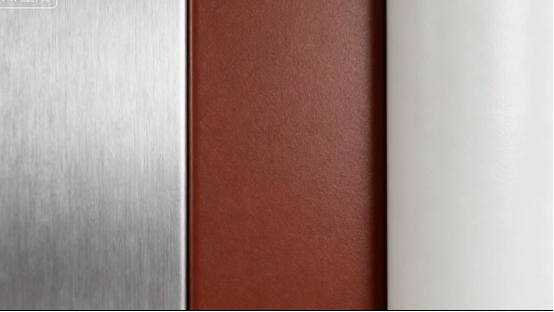

Tip 3: Prioritize Surface Treatment: Combining Corrosion Resistance and Aesthetics

Surface treatment of aluminum ceilings not only affects appearance but also directly impacts corrosion resistance and long-term maintenance.

Common processes include:

·Polymer Coating (PET): Offers a strong weather resistance, suitable for diverse environments, with a smooth, easy-to-clean surface

·Powder coating: Provides corrosion resistance, excellent weather resistance, and color stability

·Roll Coating: Delivers uniform coating results at lower cost, ideal for large-scale applications

It is recommended to select surface treatment solutions using international standard coatings with thicker layers for superior color fastness and adhesion.

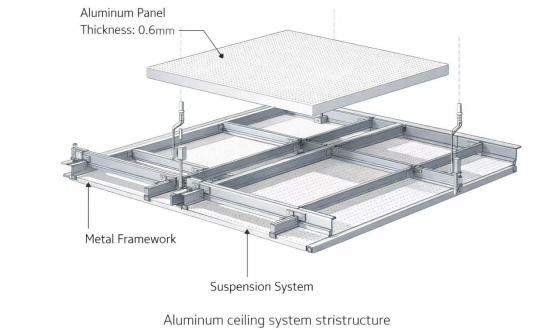

Tip 4: Consider Panel Thickness and Structural Design: Enhancing Durability and Stability

·Commercial and public spaces: 0.6 - 1.0 mm

·Large spans or high-load scenarios: ≥1.0 mm

Additionally:

·Reinforced purlin system: Enhances wind pressure resistance and bending strength

·Optimized panel gap design: Prevents deformation and acoustic noise

Tip 5: Preferred factory direct supply: More consistent quality, better pricing

Opting for factory-direct procurement of aluminum ceilings offers distinct advantages:

·Consistent quality control: High controllability from raw materials to finished products

·Customizable designs: Types, colors, and sizes tailored to specific requirements

·Greater price transparency: Eliminates markups from intermediaries

·Timely technical support: Integrated production and after-sales teams ensure rapid response

√Prioritize aluminum ceiling manufacturers with industry experience; verify their production line equipment and certifications.

Conclusion: Five Essential Material Selection Secrets for Balancing Corrosion Resistance and Aesthetics

Material Selection Criteria |

Key Considerations |

Aluminum Alloy Grade |

AA3003, AA5005 |

Surface Treatment |

PET/Powder Coating/Roll Coating |

Performance Testing |

Salt Spray, Humidity/Heat, Adhesion, etc. |

Panel Thickness |

0.6 - 1.0 mm or thicker |

Supply Model |

Direct factory supply recommended |

Selecting the right materials is essential to truly achieve both corrosion resistance and aesthetic appeal, reduce long-term maintenance costs, and enhance the overall quality of the building space and user experience.

Contact us

If you have any requirements for aluminum ceiling products or wish to obtain more technical documentation and quotations, please feel free to contact us at any time. We will provide you with the most professional products and services.

Name: Ivy

WhatsApp: +86 181 2218 7543

Email: [email protected]

Company: Guangzhou Dingchengzun Building Materials Co., Ltd.

Website: https://dingchengzunjiancai.en.alibaba.com

Regd Office: No. 126 Zhangbian Huan Village Street, Nan Village Town, Panyu District, Guangzhou

Corp Office: No. 126 Zhangbian Huan Village Street, Nan Village Town, Panyu District, Guangzhou

We look forward to collaborating with you to advance eco-friendly and safe building solutions!