Performanța superioară a aluminiului în condiții cu umiditate ridicată

Panouri de tavan din aluminiu au devenit alegerea principală pentru spațiile unde nivelurile de umiditate pun constant la încercare materialele convenționale de construcții. Spre deosebire de alternativele sensibile la umiditate, care se pot deforma, vopsi sau degrada în condiții umede, aluminiul își păstrează integritatea structurală și aspectul, indiferent de umiditatea ambientală. Această rezistență intrinsecă provine din stratul natural de oxid care se formează pe suprafața aluminiului, creând o barieră impenetrabilă împotriva vaporilor de apă și a umidității lichide. Piscinele, spa-urile, facilitățile marine și clădirile din zone cu climă tropicală beneficiază enorm de panourile de tavan din aluminiu, care nu cedează în fața efectelor distructive ale expunerii constante la umiditate. Suprafața sa neporosă împiedică absorbția apei, în timp ce rezistă dezvoltării mucegaiului și a lăcustei, probleme frecvente la materialele organice. Chiar și în medii cu umiditate extremă, cum ar fi bucătăriile comerciale sau fabricile de procesare a alimentelor, panourile de tavan din aluminiu oferă o protecție durabilă pentru tavan, necesitând întreținere minimă. Combinarea rezistenței la umiditate, a rezistenței ridicate cu greutate redusă și a flexibilității de design le face soluția logică pentru orice aplicație în care controlul umidității reprezintă o provocare constantă.

Caracteristici de Rezistență la Umiditate

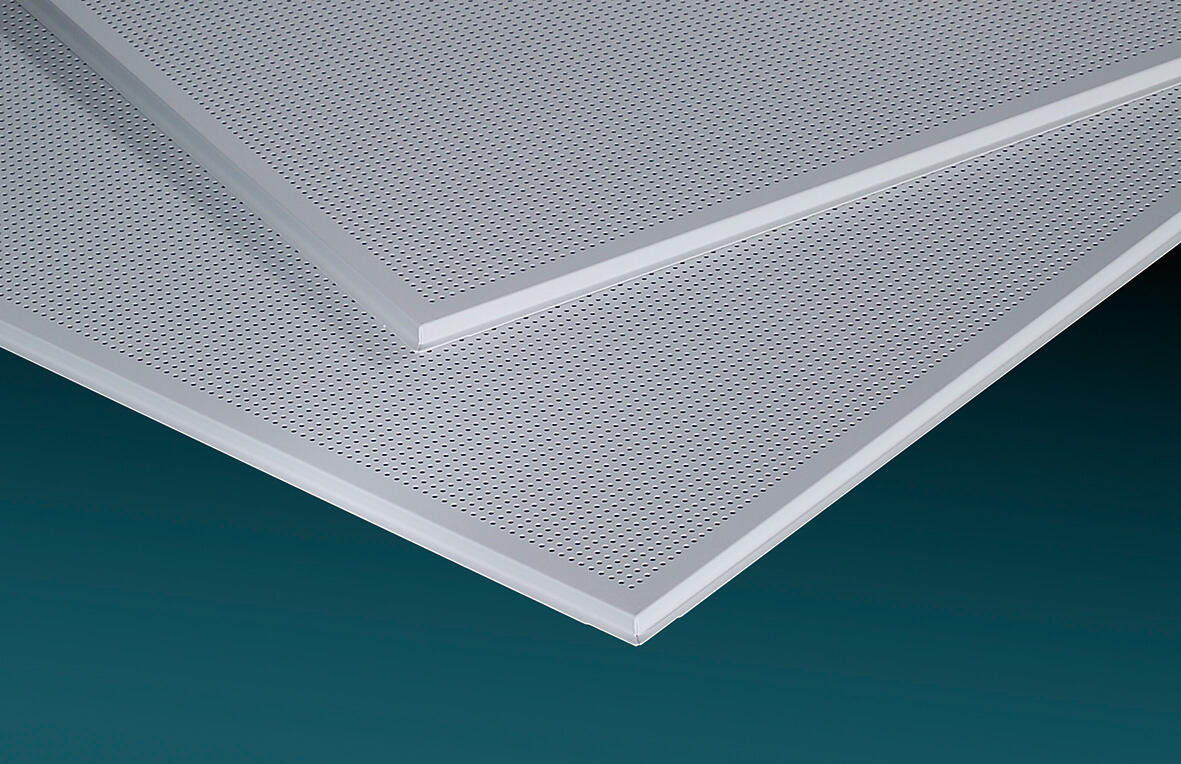

Protecție a Suprafeței Impermeabile

Panourile de tavan din aluminiu creează o barieră eficientă împotriva umezelii, prevenind deteriorarea structurilor de clădire cauzată de apă. Natură neabsorbantă a aluminiului înseamnă că umiditatea nu poate pătrunde în material pentru a cauza umflarea sau deformarea. Spre deosebire de tavanele din gips-carton sau lemn, care se deteriorează atunci când sunt expuse la umiditate, panourile de tavan din aluminiu își mențin stabilitatea dimensională chiar și în medii cu aburi. Suprafața materialului rezistă acumulării condensului, care ar putea duce la formarea și căderea picăturilor de apă. Acoperirile speciale aplicate pe panourile de tavan din aluminiu pot îmbunătăți și mai mult proprietățile de formare a picăturilor de apă, direcționând umiditatea spre punctele de scurgere. Chiar și în zonele costale cu aer încărcat cu sare, proprietățile aluminiului de a rezista coroziunii păstrează panourile de tavan în stare impecabilă timp de decenii. Posibilitățile de instalare fără cusături disponibile pentru panourile de tavan din aluminiu elimină rosturile prin care umiditatea ar putea pătrunde. Această rezistență completă la umiditate protejează atât sistemul de tavan propriu-zis, cât și infrastructura clădirii de deasupra acesteia, împotriva daunelor cauzate de umiditate.

Prevenirea mucegaiului și a lăcustei

Compoziția anorganică a panourilor de tavan din aluminiu creează un mediu neprielnic pentru dezvoltarea biologică. Spre deosebire de materialele poroase care rețin umiditatea și materiile organice, aluminiul nu oferă nicio sursă de hrană pentru mucegai sau ciuperci. Această caracteristică se dovedește deosebit de valoroasă în unitățile medicale, unde igiena tavanului influențează rezultatele pentru pacienți. Panourile de tavan din aluminiu utilizate în zonele cu piscină rezistă umidității bogate în clor, care ar degrada materiale mai slabe. Zonele de preparare a alimentelor beneficiază de capacitatea de curățare a aluminiului și de rezistența sa față de colonizarea microbiană. Suprafețele netede ale panourilor de tavan din aluminiu permit o dezinfectare completă, fără riscul de deteriorare prin apă. Chiar și în climetele tropicale, cu umiditate ridicată constantă, tavanul din aluminiu nu susține dezvoltarea fungilor care decolorează și deteriorează materialele organice. Multe sisteme de panouri de tavan din aluminiu includ acoperiri antimicrobiene pentru o protecție suplimentară în mediile sensibile. Această combinație de rezistență naturală și tratamente îmbunătățite face din aluminiu cea mai igienică soluție de tavan pentru spațiile umede.

Avantaje privind durabilitatea și longevitatea

Rezistență la coroziune în clipe umede

Panourile de tavan din aluminiu rezistă în mod natural oxidării care afectează metalele feroase în mediile umede. Stratul de oxid protector care se formează pe aluminiu își mărește rezistența atunci când este expus la umiditate, spre deosebire de oțel, care ruginește și își pierde din rezistență. Aliajele de aluminiu de calitate marină utilizate la panourile de tavan premium oferă o protecție și mai mare împotriva coroziunii provocate de apa sărată. Aceste caracteristici fac ca panourile de tavan din aluminiu să fie ideale pentru stațiunile balneare de coastă, navele de croazieră și proprietățile situate pe malul apei, unde spray-ul salin accelerează degradarea materialelor. De asemenea, facilitățile industriale care au umiditate încărcată cu substanțe chimice beneficiază de rezistența aluminiului la vapori acizi și alcalini. Materialul își păstrează integritatea structurală, în ciuda expunerii constante la aerul umed care ar cauza altor metale să se corodeze și să se degradeze. Finisajele speciale, cum ar fi vopsirea în pulbere sau anodizarea, pot îmbunătăți și mai mult rezistența panourilor de tavan din aluminiu în mediile umede și agresive. Această rezistență la coroziune se traduce prin durată mare de exploatare, fără a fi necesară înlocuirea sau întreținerea extensivă.

Rezistență la Impact în Condiții Dificile

Mediile umede coincid adesea cu alte condiții provocatoare pe care panourile de tavan din aluminiu le suportă cu ușurință. Durabilitatea naturală a materialului rezistă la daunele cauzate de curățarea frecventă în zonele umede. Panourile de tavan din aluminiu nu devin fragile sau și pierd rezistența atunci când sunt expuse la variații de temperatură comune spațiilor umede. Ele îndășească rezistența la impact indiferent de expunerea la umiditate, spre deosebire de materialele care se întepenească sau se degradează atunci când sunt ude. Această duritate este importantă în instalații sportive, unde umiditatea ridicată se combină cu posibile lovituri de mingi în tavan. Fabricile industriale beneficiază de panouri de tavan din aluminiu care rezistă la daunele cauzate de echipamente care se lovesc între ele în condiții aburinde. Chiar și în condiții extreme cazuri în caz de scurgeri de apă sau inundații, panourile de tavan din aluminiu rămân neatente, acolo unde alte materiale ar necesita înlocuire. Combinarea rezistenței la umiditate și a durabilității fizice face ca tavanurile din aluminiu să fie o investiție pe termen lung, care depășește alternativele în mediile umede.

Avantaje legate de montare și întreținere

Instalare Simplificată în Condiții de Umiditate

Panourile de tavan din aluminiu oferă avantaje practice în timpul instalării în zonele predispuse la umiditate. Spre deosebire de materialele care necesită controlul climatic în timpul montării, aluminiul poate fi instalat la orice nivel de umiditate fără riscul de deteriorare. Panourile ușoare din aluminiu reduc cerințele privind suportul structural, fiind în același timp ușor de manipulat în medii cu aburi. Multe sisteme dispun de un design cu îmbinare rapidă, care elimină necesitatea utilizării adezivilor, care ar putea ceda în condiții de umiditate ridicată. Materialul se poate tăia ușor la fața locului, fără măsuri speciale legate de expunerea la umiditate. Panourile de tavan din aluminiu se pot adapta la mișcările clădirii cauzate de fluctuațiile de umiditate, fără a crăpa sau deforma. Instalatorii apreciază faptul că lucrează cu un material care nu este compromis de expunerea accidentală la apă în timpul procesului de construcție. Aceste beneficii legate de instalare se traduc într-o finalizare mai rapidă a proiectului și în costuri reduse cu forța de muncă în proiectele aflate în medii umede.

Performanță cu întreținere minimă

Cerințele minime de întreținere ale panourilor de tavan din aluminiu le fac ideale pentru spațiile umede greu accesibile. Spre deosebire de materialele care necesită vopsire frecventă sau etanșare, aluminiul își păstrează aspectul cu o curățare simplă. Panourile de tavan din aluminiu de înaltă calitate rezistă la pete provocate de depunerile minerale în zonele cu condens din cauza apei dure. Culoarea și finisajul lor rămân vibrante, în ciuda expunerii constante la aerul umed care ar decolora alte materiale. Întreținerea curentă presupune doar ștergerea ocazională cu agenți de curățare blânzi, fără a fi necesare tratamente speciale sau acoperiri. Panourile de tavan din aluminiu nu necesită inspecții pentru mucegai și remedieri, ca în cazul materialelor organice, în condiții umede. Chiar și în medii comerciale cu cerințe stricte de igienă, tavanurile din aluminiu simplifică procedurile de curățare, asigurând conformitatea. Economiile de timp și costuri rezultate din întreținerea redusă fac panourile de tavan din aluminiu deosebit de valoroase în facilitățile mari și umede, cum ar fi parcurile acvatice sau fabricile de procesare a alimentelor.

Flexibilitate în Design pentru Spațiile Umede

Opțiuni Estetice pentru Medii Solicitante

Panourile de tavan din aluminiu oferă versatilitate în design fără a compromite rezistența la umiditate. Tehnici moderne de producție realizează panouri de tavan din aluminiu în practic orice culoare, model sau finisaj, pentru a se potrivi schemei de design. Panourile perforate din aluminiu asigură control acustic în spațiile umede unde reducerea zgomotului este importantă. Finisajele reflectorizante pot îmbunătăți distribuția luminii în zonele interioare cu aburi, cum ar fi piscinele acoperite. Materialul acceptă imprimarea digitală pentru grafică personalizată în medii comerciale umede, cum ar fi magazinele de flori. Panourile de tavan din aluminiu pot replica aspectul lemnului sau al altor materiale, oferind în același timp o rezistență mult mai bună la umiditate. Arhitecții aleg aluminiul pentru spațiile umede deoarece acesta își păstrează estetica în condiții în care alte materiale s-ar decolora sau degrada. Capacitatea de a combina performanța cu designul face panourile de tavan din aluminiu potrivite pentru spații umede de lux, cum ar fi spa-urile premium și holurile de resort.

Configurări personalizate pentru aplicații speciale

Producătorii realizează panouri pentru tavan din aluminiu în configurații specializate pentru a face față unor provocări specifice mediilor umede. Panourile pentru tavan din aluminiu ventilate favorizează circulația aerului pentru a reduce acumularea de condens în zonele extrem de umede. Camerele curate cu umiditate ridicată folosesc panouri pentru tavan din aluminiu fără cusături care respectă standardele stricte privind particulele. Zonele exterioare cu climă umedă beneficiază de panouri pentru tavan din aluminiu cu o rezistență crescută la radiațiile UV, destinate spațiilor acoperite. Panourile pentru tavan din aluminiu cu protecție împotriva exploziilor sunt utilizate în instalații industriale umede, unde există vapori inflamabili. Prezenta materialului permite realizarea unor forme și dimensiuni personalizate, adaptate configurațiilor neobișnuite ale spațiilor umede. Aceste soluții specializate cu panouri pentru tavan din aluminiu răspund cerințelor specifice, păstrând toate beneficiile oferite de rezistența la umiditate și durabilitate. Adaptabilitatea aluminiului ca material pentru tavan asigură o soluție optimă pentru practic orice aplicație în medii umede.

Întrebări frecvente

Cum se compară aluminiul cu PVC-ul pentru panourile de tavan în zonele umede?

Deși PVC-ul rezistă la umiditate, panourile de tavan din aluminiu oferă o rezistență superioară la foc, durabilitate și sustenabilitate ecologică. Aluminiul nu se va deforma sau deveni fragil în timp, ca în cazul PVC-ului, care poate suferi în urma fluctuațiilor extreme de temperatură frecvente în spațiile umede. Panourile de tavan din aluminiu își păstrează aspectul mai mult timp, fără a se îngălbeni sau a se păta.

Pot apărea probleme de condens pe panourile de tavan din aluminiu?

Panourile de tavan din aluminiu instalate corect, cu o izolație și o ventilație adecvate, nu vor cauza probleme de condens. Conductivitatea lor termică ajută de fapt la gestionarea diferențelor de temperatură care duc la condens. Unele sisteme de panouri de tavan din aluminiu includ rupturi termice sau canale de condens pentru o protecție suplimentară în condiții extreme de umiditate.

Sunt panourile de tavan din aluminiu zgomotoase în medii umede?

Panourile de tavan din aluminiu perforat cu suporturi absorbante de sunet oferă o performanță acustică excelentă în spațiile umede. Materialul nu devine mai zgomotos atunci când este expus la umiditate, spre deosebire de unele materiale care pot scârțâi sau crăpa atunci când sunt umede. Stabilitatea aluminiului asigură o performanță acustică constantă, indiferent de nivelul de umiditate.

Cum diferă cerințele de curățare pentru panourile de tavan din aluminiu în medii umede față de cele uscate?

În mediile umede, panourile de tavan din aluminiu pot necesita o curățare ușor mai frecventă pentru a preveni acumularea de depuneri minerale din condens. Totuși, procesul de curățare rămâne simplu - de obicei ștergerea cu o soluție de detergent blând. Frecvența crescută de curățare este mult mai puțin solicitantă decât întreținerea necesară altor materiale afectate de umiditate.

Cuprins

- Performanța superioară a aluminiului în condiții cu umiditate ridicată

- Caracteristici de Rezistență la Umiditate

- Avantaje privind durabilitatea și longevitatea

- Avantaje legate de montare și întreținere

- Flexibilitate în Design pentru Spațiile Umede

-

Întrebări frecvente

- Cum se compară aluminiul cu PVC-ul pentru panourile de tavan în zonele umede?

- Pot apărea probleme de condens pe panourile de tavan din aluminiu?

- Sunt panourile de tavan din aluminiu zgomotoase în medii umede?

- Cum diferă cerințele de curățare pentru panourile de tavan din aluminiu în medii umede față de cele uscate?