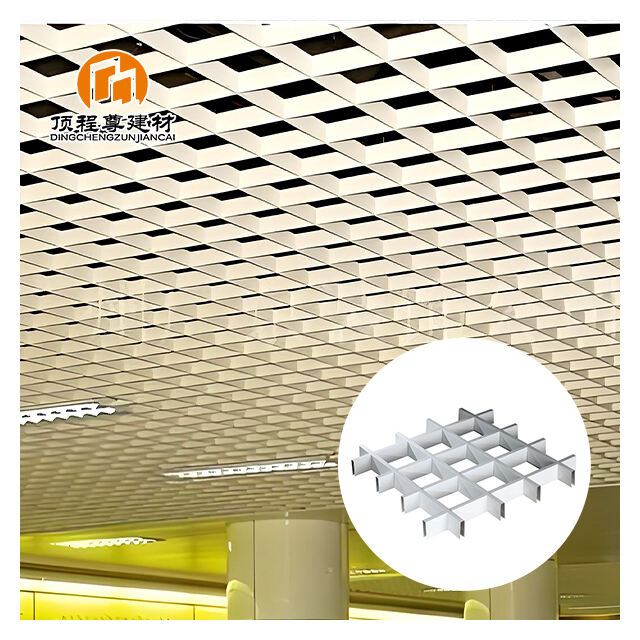

grille métallique de plafond suspendu

Un système de grille en métal pour plafond suspendu sert de cadre fondamental pour les installations de plafonds suspendus, offrant une solution sophistiquée pour les espaces intérieurs modernes. Ce système ingénieux se compose de composants métalliques fabriqués avec précision, y compris des longerons principaux, des traverses et des angles de mur, qui s'interconnectent pour créer un réseau de grille solide. Le système est généralement suspendu au plafond structurel à l'aide de supports en fil, créant un espace plénum qui accueille les services essentiels du bâtiment tels que les conduits HVAC, les câbles électriques et la plomberie. La conception de la grille incorpore des principes d'ingénierie avancés pour garantir l'intégrité structurelle tout en maintenant un attrait esthétique. Les grilles métalliques modernes présentent des technologies de revêtement spécialisées qui améliorent la durabilité et la résistance à la corrosion, avec des options telles que l'acier galvanisé et les constructions en aluminium. La modularité du système permet une intégration facile des luminaires, diffuseurs d'air et divers matériaux de dalles de plafond, le rendant hautement adaptable aux exigences architecturales variées. Une précision d'installation est garantie grâce à des fonctionnalités d'alignement intégrées et des capacités de nivellement, assurant un fini professionnel à chaque fois. La capacité de charge du système de grille est soigneusement calculée pour supporter à la fois les dalles de plafond et les équipements supplémentaires tout en maintenant la stabilité structurelle et les normes de sécurité.